Image credit: SICK

In applications that involve wet or humid environments — especially those in the food and beverage industry — a component’s IP (International Protection) rating for ingress of dust and water is an important factor in its selection. But even if a component is rated as dust-proof and protected against the forceful water jets used during washdown and sanitizing operations, the component’s housing is still fully exposed to the chemicals used in the cleaning process. And if the housing is unable to withstand these harsh chemicals, the component’s IP rating will eventually (if not immediately) become irrelevant.

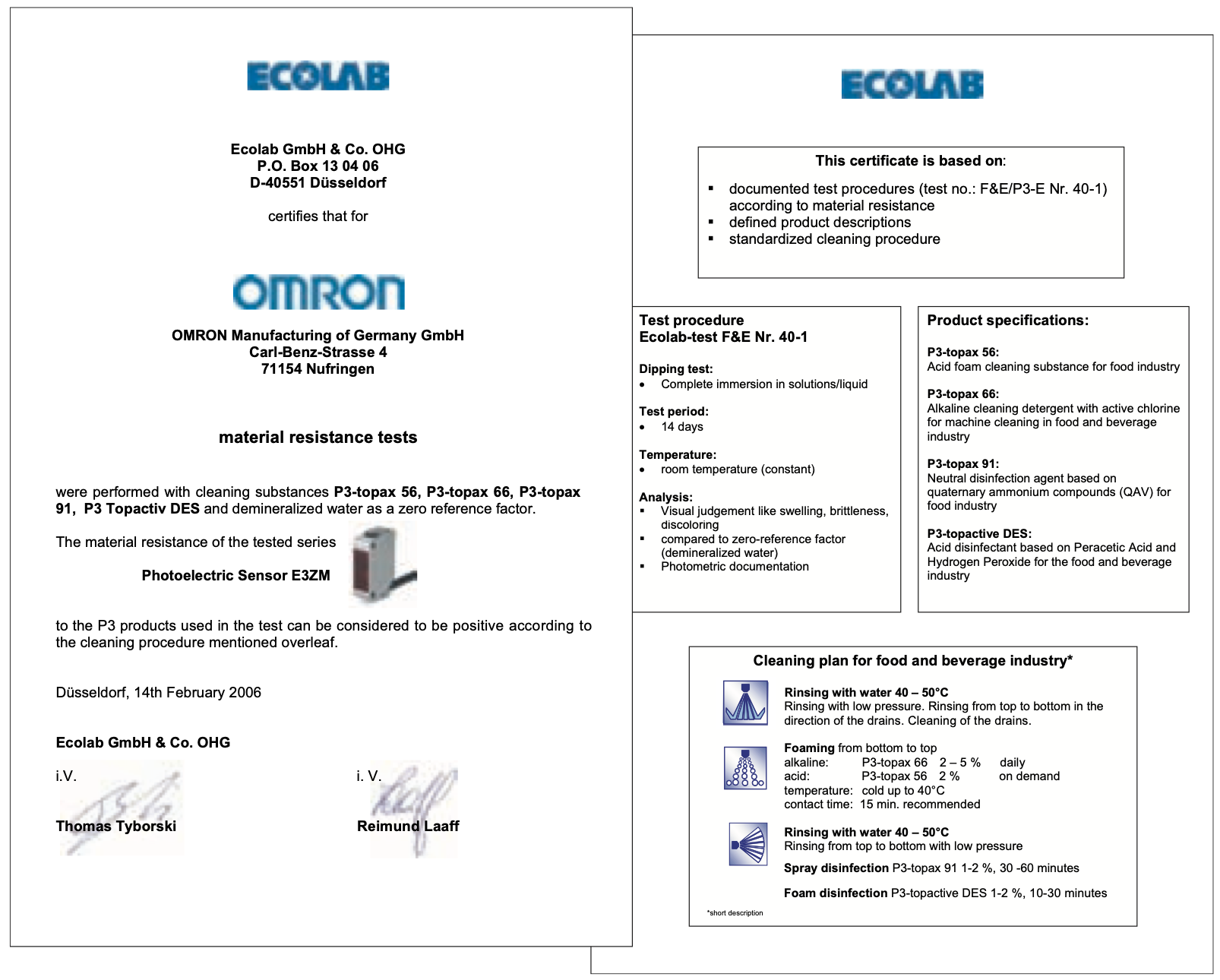

To address the need for verification of a component housing’s ability to withstand cleaning chemicals, Ecolab offers chemical compatibility testing and certification.

Ecoloab is a known for providing water, hygiene, and infection-prevention products and services, including solutions for food and beverage manufacturers and other automation-intensive industries. To support the need for hygiene and safety in these industries, the company also provides testing services related to sanitation and cleanliness, including a test that determines a material’s resistance to a range of cleaning chemicals used in the food and beverage industry.

Ecolab’s material resistance test is often used for components such as sensors, light curtains, actuators, cables, and connectors, but it can also be used for material coatings applied to these and other components. The purpose of the test is to simulate the chemical exposure a material will be subjected to during washdown operations and determine whether the material exhibits resistance or susceptibility to those chemicals.

The material resistance test is conducted with a variety of cleaning chemicals specifically developed for the food and beverage industry, including combinations of the following (and others as required):

- Acid disinfectants

- Acid foam cleaners

- Alkaline, chlorine-free foam cleaners

- Alkaline foam detergents with chlorine

- Neutral disinfectants based on quaternary ammonium compounds (QAC)

Materials or component samples are submerged in the selected cleaning agents for a specified period — typically 14 or 28 days — at room temperature (20°C). After the “dipping test,” the specimens are visually inspected for swelling, brittleness, and discoloration, as compared to the zero-reference factor (components submerged in demineralized water).

If the samples perform satisfactorily, a test certificate is provided, describing the chemicals used in the test and stating that the material resistance of the samples to the cleaning products used “can be considered positive.” As part of the test certificate, Ecolab also provides a recommended cleaning plan, specifying the suggested cleaning chemicals and their concentrations, application method (rinse or foam), and contact time.

Numerous manufacturers of automation components offer products — particularly those used in the food and beverage industry — that are certified by Ecolab. This certification is often found alongside a product’s IP rating, as the two criteria naturally go hand-in-hand.

Leave a Reply

You must be logged in to post a comment.