Electrical enclosures, such as those for motors, sensors, and HMIs, are often given what is known as an IP rating, consisting of the two letters, “IP,” followed by two numeric digits — IP65, for example. This IP rating indicates the amount of protection the enclosure provides against the ingress of solid particles and liquids.

Unlike other designations that are often applied to industrial equipment, such as “high torque,” or “waterproof,” IP ratings are specific and internationally accepted. Both the rating system and the testing process are defined by the International Electrotechnical Commission in standard IEC 60529.

The initials “IP” are often taken to mean “Ingress Protection,” but according to IEC 60529, the correct term is “International Protection.”

Decoding the IP rating system

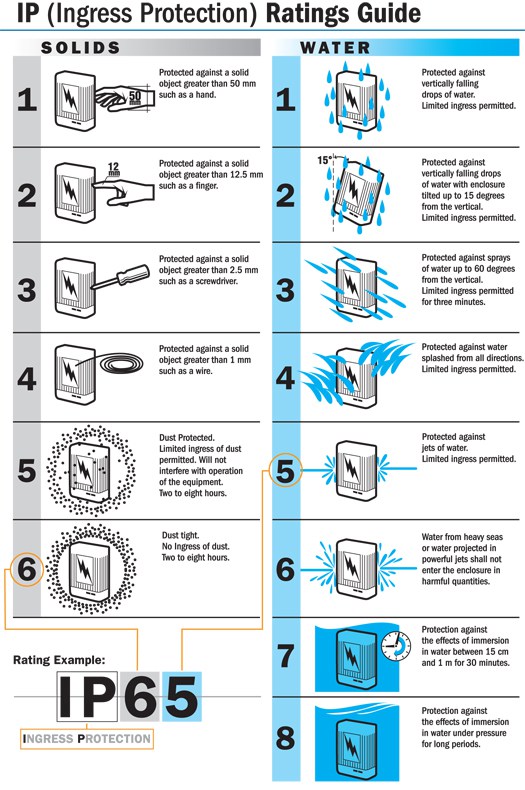

The first numeric digit in the IP rating specifies the protection level against foreign objects, based on the size of the object (12 mm versus 1 mm, for example). The higher the number, the better the protection, with the maximum rating being 6, which indicates a dust-tight enclosure. An enclosure that meets a stated degree of protection against solid objects must also meet all the lower degrees of protection. For example, an enclosure rated IP4x must also meet IP3x, IP2x, IP1x, and IP0x requirements.

The second numeric digit specifies the protection level against the ingress of liquids, based on the amount of liquid and the direction of its approach to the object. The test to determine protection against liquids is time-based, and where applicable, includes specification of nozzle size, distance from object, and delivery pressure.

It’s important to note that for protection against liquids, an enclosure must meet all the protection requirements below its rated designation, up to and including level 6 protection. Enclosures rated IP-7 and IP-8 do not have to comply with IP-5 and IP-6 requirements for water jet exposure.

If a device has not been tested or rated for one of the criteria, that digit is replaced with an “X.” For example, IPX4.

An important extension of the IP ratings comes from the DIN standard 40050-9 (which has been rolled into the ISO standard 20653:2013). This DIN standard adds an additional letter, “K,” to indicate environmental sealing. This additional specification applies only to IP6- ratings, which means the device must be dust-tight before the environmental sealing (“K”) designation can be applied.

An IP6-K rating, such as IP69K, means the device can withstand high-pressure cleaning and steam cleaning, with the test consisting of 80° C water delivered at pressures of 8 to 10 MPa (80 to 100 bar) at a rate of 14 to 16 L/min, with the nozzle located 10 to 15 cm from the device at angles of 0, 30, 60, and 90 degrees for 30 seconds each. Food processing and pharmaceutical applications often require electrical equipment that meets IP69K standards, due to the use of high-temperature, high-pressure liquids and steam for cleaning.

How are NEMA enclosure standards different?

NEMA — the National Electrical Manufacturers Association — also provides a standard, referred to as NEMA 250-2014, that defines an enclosure’s ability to provide environmental protection.

While the NEMA and IEC standards have the same general purpose, the protection requirements and test standards specified by NEMA 250 are, in some cases, more rigorous. For example, the NEMA 250 standard addresses environmental conditions such as corrosion, icing, oil, and coolants — none of which are addressed by the IEC 60529 standard.

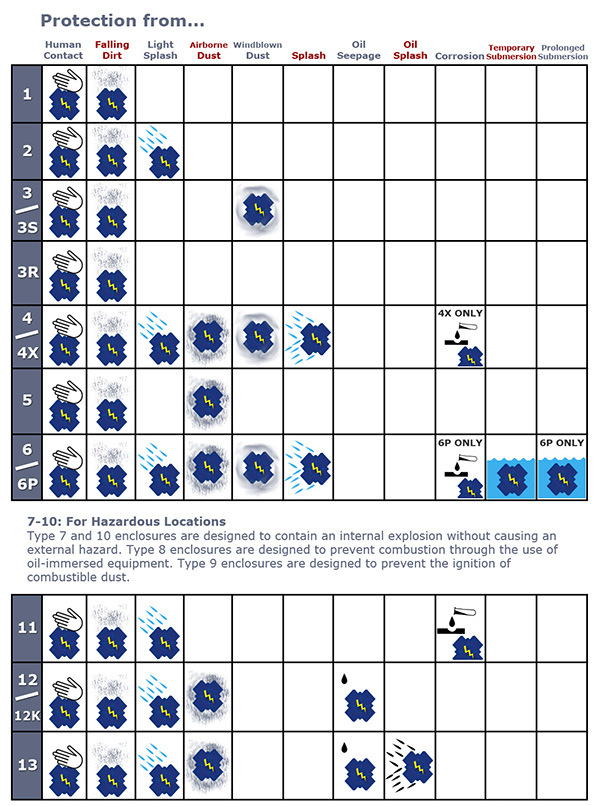

Protection ratings in the NEMA 250 standard are categorized by whether the equipment is constructed for indoor or outdoor use, and whether it is applied in non-hazardous or hazardous locations. For example, NEMA enclosure Types 1, 2, 4, 5, 6, 12, and 13 are applicable to enclosures constructed for indoor use in non-hazardous locations. Types 3, 4, and 6 apply to enclosures constructed for outdoor use in non-hazardous locations. (Note that there is some overlap between indoor and outdoor use in Types 4 and 6.) Types 7, 8, 9, and 10 apply to enclosures in hazardous locations.

The table below is a simplified description of the NEMA enclosure ratings. For the full definitions and specifications, see the NEMA Enclosure Types document.

Image credit: Marshall Wolf Automation

Can IP and NEMA enclosure ratings be cross-referenced?

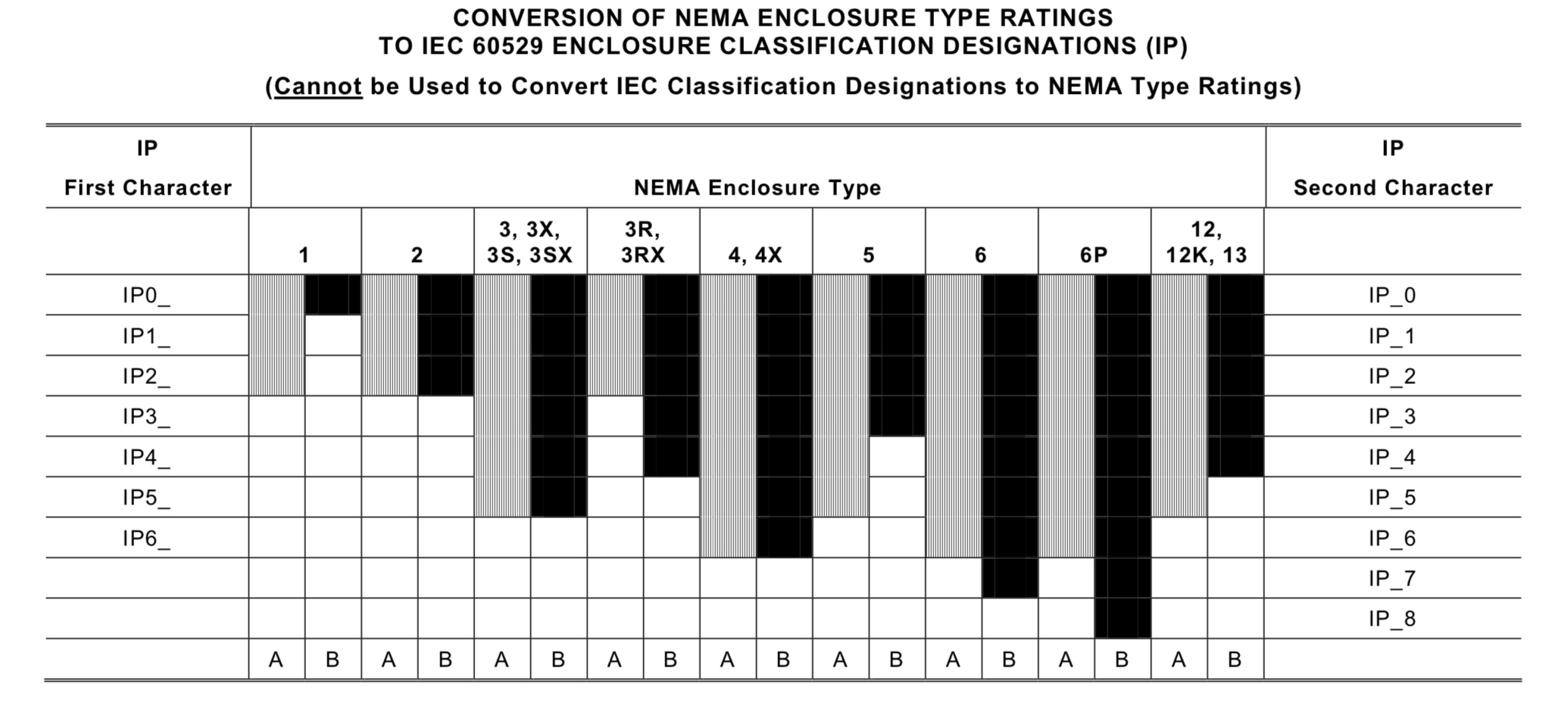

In some cases, it is possible to convert NEMA Type ratings to IEC IP ratings, but because NEMA ratings include requirements not covered by IEC, it’s not possible to convert an IP rating to a NEMA Type rating, as the IP rating would not cover the same conditions as the NEMA rating.

The chart below, provided by NEMA, can be used as a guideline for converting NEMA Type ratings to IEC IP ratings.

Feature image credit: Unmanned Systems Source

Leave a Reply

You must be logged in to post a comment.