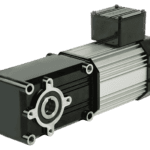

Gearmotors use gears to reduce speed, which makes more torque available. The kind of gears used in gearmotors have an impact on the available torque, but also on things like noise levels and accuracy. In fact, one of the more common sources of inaccuracy in gearmotors is due to gear backlash. So reducing the amount of backlash will lead to a more accurate gearmotor.

There are a number of common ways to reduce backlash in gears. These include methods like pre-loading as well as design with gears that eliminate or at least minimize backlash.

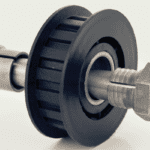

One way to reduce backlash is to use precision gears. The focus on manufacturing in precision gears is tighter tolerances, so all around the gear will be a tighter, more precise fit. And the tighter fit means less play in the gear teeth, which is the cause of backlash in the first place. Of course, precision gears are more expensive, but if the application calls for high accuracy, then precision gearing may be the way to go.

From a gear design perspective, an easy way to reduce backlash is to make sure the teeth mesh tightly together. This is typically done by shortening the center distance between gears. As for pre-loading, this can be done using a spring mechanism to hold the gears firmly in place. This also eliminates the play between the gear teeth and thus eliminates backlash.

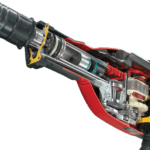

Of course, the type of gears used can also have a large impact on the amount of backlash. So for instance, some gear types such as strain wave gears have zero backlash.

Leave a Reply

You must be logged in to post a comment.