As mentioned in a previous blog posting summarizing the news from the recent Pack Expo, there is an ongoing and renewed interest in energy consumption in manufacturing plants. Plant managers and engineers are looking beyond some of the more obvious starting points such as lighting to the machinery in plants, specifically the motors and systems packed into machines.

According to the federal government’s Energy Star program, industrial energy use is responsible for almost 30 percent of all U.S. greenhouse gas emissions, which contribute to global climate change. And some of the most important recommendations for implementing an energy saving program into a plant include measuring and tracking energy performance as well as improving common plant systems such as motors, compressed air, steam and process heating, among others.

Implementing these measures not only helps reduce greenhouse gas emissions but translates directly into cost savings for the plant as a whole.

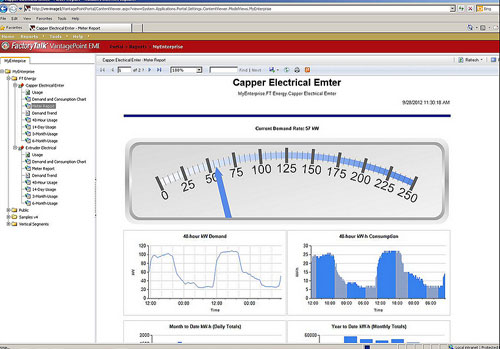

To that end, more companies are including energy management products as part of their product offerings to customers increasingly concerned with energy usage. One recent example is Rockwell Automation. The company recently released a suite of energy management software capabilities which according to the company will help their customers “view resource consumption in relation to specific units, lines and machines so they can make more informed energy decisions.”