Since the 1980s, drive electronics have been part of NORD DRIVESYSTEMS’ modular product line. By combining electronic control products with gear units and electric motors, the company offers complete drive systems from a single supplier. NORD’s drive electronics portfolio now includes a range of products intended for use across industrial applications.

In selecting, configuring and designing drive systems, NORD considers motion along with energy use, operational reliability, total cost of ownership and application-specific requirements. The company says its modular approach allows drive solutions to be configured to meet different needs, with more than 20 million standard configurations possible. NORD serves customers across more than 100 industries.

NORDAC variable frequency drives: compatible and multi-functional

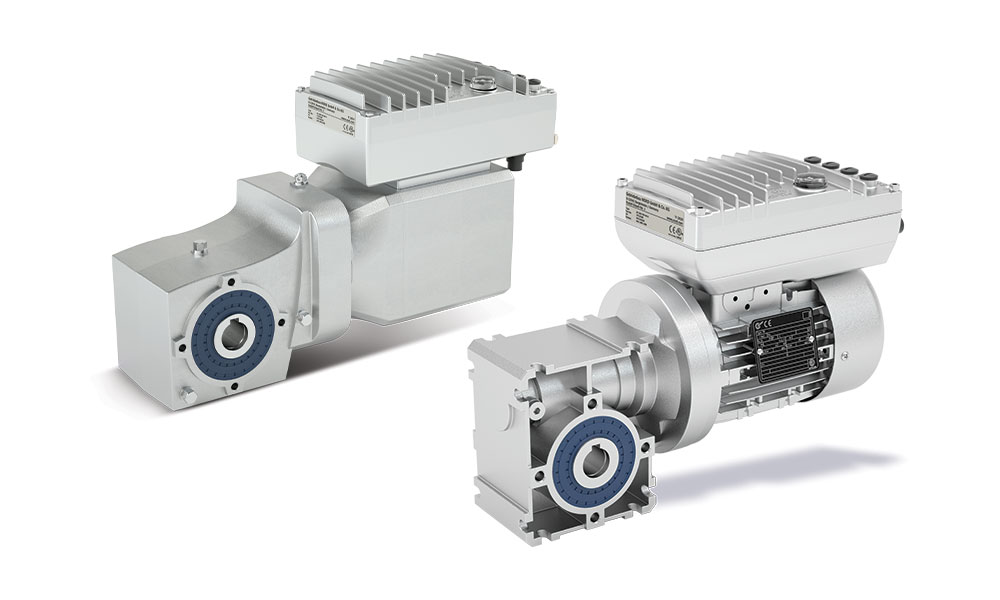

NORDAC variable frequency drives and motor starters are compatible with NORD’s gear motor portfolio and offer scalable functions, straightforward installation and precise control. An integrated PLC supports modular and autonomous production systems, and NORDCON tools help streamline setup and adjustments. The products are available in centralized control-cabinet versions and decentralized on-application versions for use with asynchronous or synchronous motors.

NORDAC PRO variable frequency drives are centralized, control-cabinet units offered in six frame sizes. They include an integrated multi-protocol Ethernet interface and a multi-encoder interface for multi-axis control. Features across the series include sensorless current vector control to help maintain constant speed under changing loads and high starting torque, a 200% overload reserve for lifting applications and an integrated brake chopper for four-quadrant operation. The drives use a compact book-size format for space-saving installation in control cabinets.

NORDAC LINK variable frequency drives and motor starters are designed for installation near the motor and can be configured for a range of applications. Plug-and-play setup supports straightforward installation. An integrated maintenance switch and local manual controls support commissioning and servicing. NORDAC LINK also includes functional safety features intended to protect equipment and operators during operation.

NORDAC FLEX variable frequency drives use a modular design with scalable functions for motor or wall mounting. Optional integrated modules, including fieldbus interfaces, control options and functional safety, allow added features as needed. Accessories and configuration choices support versions tailored to specific system requirements.

NORDAC ON/ON+ variable frequency drives are decentralized drives for horizontal conveyor applications. NORDAC ON is for asynchronous motors, while NORDAC ON+ is for synchronous motors and is used with NORD’s IE5+ motor line. Standard functions include digital inputs for sensors, brake management for brake actuation, and POSICON positioning mode. The drives have a compact, fully pluggable design intended for IIoT installations.

NORD is developing new versions of the NORDAC ON and NORDAC ON+ to add safety functions such as SLS, SMS and SSM, in addition to the STO and SS1 functions already offered. The company said the drives will support PROFIsafe and FSoE interfaces, allowing integration into existing Ethernet networks and use as stand-alone units.

The NORDAC ON PURE is expected to be available soon for wash-down environments with caustic cleaners. It uses NORD’s NXD tupH sealed surface conversion system and a smooth, rounded housing with fewer input and output plug connections. NORD said the design will enable fully aluminum drive systems with corrosion resistance comparable to stainless steel.

For more information, visit nord.com.

Leave a Reply

You must be logged in to post a comment.