Since the Functional Mock-up Interface (FMI) technical standard was introduced in 2010, simulation models have been used more often in system planning. NORD DRIVESYSTEMS uses data-based simulations to develop components and drive solutions and, more recently, to build digital twins for system development. The company says this approach helps engineers evaluate drive concepts earlier in the planning process, including for complex systems, which can shorten project timelines and support system availability.

Virtual commissioning is available through the myNORD Online Customer Portal. Users configure a drive system by selecting options such as performance, mounting, and outputs. After completing the configuration, they can request a simulation model of the configured drive system. The process was developed by NORD in cooperation with machineering GmbH & Co. KG, a Munich-based software company focused on virtual commissioning.

One advantage of digital twins is earlier access to a working model of the full system. Using myNORD models in a simulated environment allows testing before products are ordered and assembled. If changes are needed, they can be made using the model data, which can help identify issues earlier in development and reduce the risk of later disruptions.

After the virtual drive system is tested and approved by the customer, NORD manufactures and delivers the physical solution. Commissioning can be completed faster because the drives have already been integrated into the control system in the simulation. NORD says the process from configuration to commissioning can be reduced from several months to a few weeks.

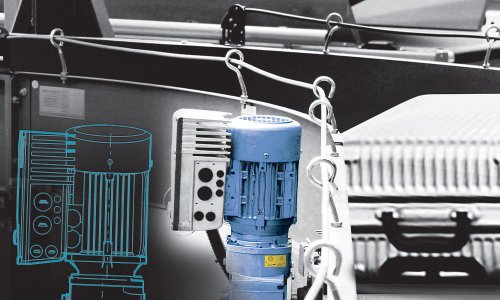

Virtual commissioning can be useful for technically complex systems because it allows teams to address potential issues earlier in the project. For its initial simulation models, NORD is focusing on components used in automated production processes, including its synchronous motors, along with related gear units and variable-frequency drives. The company said it plans to expand the simulation models to additional product areas over time.

For more information, visit nord.com.

Leave a Reply

You must be logged in to post a comment.