IMS Gear has enhanced its product offering with an all New PK/PM 22 planetary gear series to bring it in line with state-of-the-art engineering. The essential features include a revised gear design with optimized noise behavior, improved efficiency and a new rigid flange design. An all-plastic planetary gear unit has also been included in the line-up.

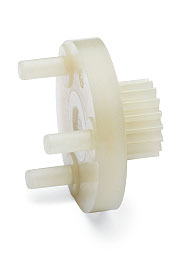

All-plastic planetary gear

Plastic planetary gear carrier

The latest generation of the 22 Series planetary covers an even wider range of requirements in high performance applications. The PM 22 features a steel internal ring gear with an external black powder coating – the optimum regarding corrosion resistance, service life and optical appearance. Additional features in the modular design are the optimized gear tooth profiles which reduce gear noise and provide smoother transmission of motion. The higher molecular weight of steel also helps to dampen and attenuate noise. Permissible output torque values were increased in this case to as much as 1.0 Nm under continuous load.

Old gear rim (left); new (right) with radial stiffening

To meet the increasing cost pressure in the market for large volume applications, a totally new low-cost all-plastic PK 22 planetary drive has been developed, with flanges, planetary gear carriers and all gearing made of plastic. The new gear units are particularly suitable for applications in which high torque values and ambient temperatures are not decisive factors. Another advantage over metal is their low weight. All reductions were maintained for the all-plastic planetary gear carriers, allowing the easy change to the new PM/PK 22 series without modifying the motors or the connecting dimensions.

PM 22 exploded view

The advanced 22 Series modular planetary gear units in all metal, all plastic or any combination of both can be easily fitted onto any motor, including NEMA 8 & 11, and so promote the forward development in supplying the optimum drive solution to meet your stringent demands.

www.imsgear.us

Leave a Reply

You must be logged in to post a comment.