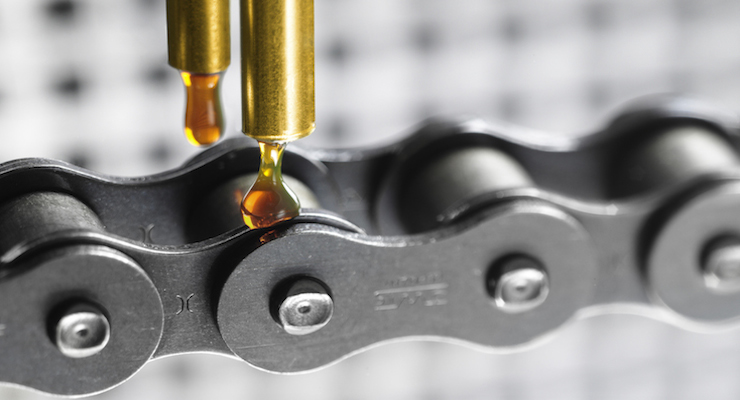

In any system with moving parts, lubrication is essential. Lubrication functions to reduce friction, which dissipates heat and protects components from corrosion and wear.

Lubricants are typically classified as either one of two kinds; oils or greases. Oil-based lubricants can be made from petroleum sources or newer synthetic oils. Greases have an oil base to which various thickening agents are added.

Lubricants are used across a range of applications, from general-purpose industrial uses to special requirements and applications. There are greases designed for high temperatures and low temperatures, as well as for high-load applications. Some greases are designed to be biodegradable and there are also food-grade greases for food and beverage production facilities. No matter the application, the most important parameters for evaluating lubricants include operating temperature, load, speed, viscosity and application rate.

Lubrication for motion control

Particularly in motion control applications, lubrication plays a critical role. Many kinds of components need lubrication, from ballscrews and leadscrews to bearings, gears and motors.

Take ballscrews, for instance. Because ballscrews are a bearing system, they require some type of lubrication to avoid metal-to-metal contact of the balls in the raceway. While the lubricant can be either oil or grease, it’s advisable to avoid solid additives (such as graphite) as they will clog the recirculation system. An NLGI no. 2 type grease is recommended, but it should also depend on the application, whether food-grade or another special type of lubrication is required. Ballscrews, especially those used in machine tools, generally require lubricants with EP additives to prevent excessive wear. The frequency of lubrication will vary depending on factors such as the move cycle characteristics or contamination in the environment.

Leadscrew mechanisms using bronze nuts also need a lubricant, usually a thick damping grease. Leadscrew assemblies with plastic nuts can run well without lubricant due to internal lubricants in the nut materials, but the use of a gel-type lubricant will help increase allowable loading and extend life by reducing friction. If particulates are present, the screw should be cleaned before reapplying lubricant. Scheduled preventative maintenance should occur when there is no visible film remaining on the flanks of the screw thread.

As for grease, it shouldn’t be used in environments with significant particulate or debris that can load the grease and cause it to become an abrasive slurry. In this type of application, dry film lubricant should be used instead. PTFE coating is a dry film that creates a lubrication barrier between a metal substrate and a polymer bushing or lead nut. It’s well suited for use with plastic nuts and stainless-steel leadscrews. Lubrication maintenance intervals can be eliminated and the coating does not attract particulate like a gel lubricant.

Bearing lubrication: oil or grease?

Grease lubrication is generally restricted to relatively slower-speed applications due to reduced capability for frictional heat dissipation as compared with that of oil.

There are a number of advantages grease has over oil:

- Simplifies seal design, acts as a barrier to contamination and is a sealant

- Permits pre-lubrication of sealed or shielded bearings

- Generally requires less frequent lubrication

- Less costly

Oil lubricants are most common in high-speed, high-temperature applications that need heat transfer away from working bearing surfaces. Bearing oils are either a natural mineral oil with additives to prevent rust and oxidation or a synthetic oil. In synthetic oils the base is usually polyalphaolefins (PAO), polyalkylene glycols (PAG) and esters. Although similar, synthetic and mineral oils offer different properties and are not interchangeable. Mineral oils are the more common of the two.

The most important characteristic when specifying oil for a bearing is viscosity. Viscosity is a measure of a fluid’s internal friction or resistance to flow. High-viscosity fluids are thicker like honey; low-viscosity fluids are thinner like water. Fluid resistance to flow is expressed in Saybolt Universal Seconds (SUS) and centistokes (mm2/sec, cSt). The difference in viscosity at different temperatures is the viscosity index (VI). An oil’s viscosity is correlative to the film thickness it can create. This thickness is crucial to the separation of the rolling and sliding elements in a bearing. Bearings in some applications use oil, but grease is the lubricant of choice for 80 to 90% of bearings. Grease consists of about 85% mineral or synthetic oil with thickeners rounding out the rest of the grease volume.

The thickeners are usually lithium, calcium or sodium-based metallic soaps. Formulations for higher-temperature applications often include polyurea. The higher viscosity of grease helps contain it within the bearing envelope. The most important considerations when choosing a grease are the base oil viscosity, rust-inhibiting capabilities, operating temperature range and load-carrying capabilities.

Leave a Reply

You must be logged in to post a comment.