In food and beverage lines, conveyors move parts into and out of machines, or they move parts through machines, act as a bridge between machines, or act as the main artery of a production line. An increasingly important capability of conveyor systems is to deliver more precise positioning.

Positioning accuracy is influenced by friction, either the slipping of the belt on the gear sprocket or micro slipping of product on the belt from the effects of inertia.

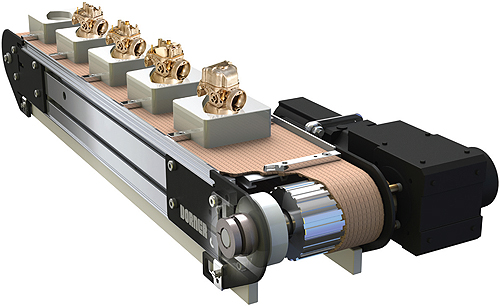

Dorner’s Precision Move 2200 and 3200 Series conveyors eliminate the contributors to inaccurate positioning. This line of conveyors uses positive drive belting. Teeth in the sprocket lock into teeth in the underside of the belt to eliminate slippage.

For the slippage that occurs with product on top of the belt, Dorner offers conveyors with fixture attachments that hold product in place.

A servo drive ensures that the conveyor belt delivers product to a precise position. The 3200 Series has an accuracy of 0.20 in. and the 2200 Series conveyor package has an accuracy of ± 0.40 in. Use of this approach can eliminate the need for vision systems to oversee item or part placement.

The 3200 Series offers single belt widths up to 18 in., which gives you flexibility in direct mounting of parts or pallets/pucks. The lengths range from 2 to 50 ft. The unique fixture attachments have an accuracy of ± 0.005 in. between them.

The 3200 series can handle loads to 750 lb, and belt speeds to 520 fpm. The belts have a 21-tooth H (1/2 in.) pitch profile; width ranges from 3.75 in. to 18 in. The belts of this positive drive system will not slip. The conveyor is accurate to

±0.01 in. The servomotor is accurate to ±0.02 in.

The 2200 series handles loads to 200 lb, and belt speeds to 370 fpm. The belts have a 12 tooth T10 Profile. Belt width ranges from 1.75 to 24 in. Like the 3200 series, these positive drive systems will not have belt slippage. Conveyor accuracy is ±0.02 in. Conveyor lengths range from 1.5 to 30 ft. Servo accuracy is ±0.04 in.

Dorner

www.dornerconveyors.com

Leave a Reply

You must be logged in to post a comment.