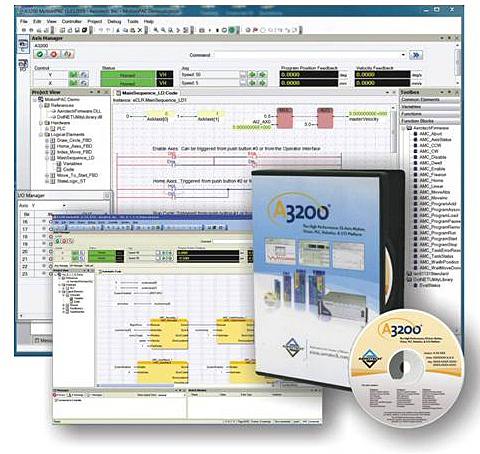

Aerotech (www.aerotech.com) has announced that it has integrated the A3200 MotionPAC software-based programmable logic controller (PLC) with its A3200 motion controller to optimize programming quality and efficiency while reducing development time.

Compliant with PLCopen and IEC 61131-3, the MotionPAC can be used in conjunction with AeroBasic programs or independently for full machine control. It also allows users to program in Function Block Diagrams (FBD), Ladder Diagrams (LD) or Structured Text (ST). Its integrated automation reduces commissioning and programming time by 30 percent to 50 percent, making it ideal for use in machine control program development.

Since it is integrated with the company’s A3200 motion controller, users can directly command coordinated, asynchronous, geared, blended or cammed motion from FBD, LD and ST. MotionPAC also allows users to specify moves as absolute or relative either in English or metric units.

Meanwhile, programmers can create shared Tags and variables that are referenced by Name in the A3200 tools, AeroBasic, Operator Interface, C or .NET programs. MotionPAC automatically handles memory management for all variables and Tags.

Its tools, which include user definable libraries (FBD, LD, ST or .NET), global Tag database, integrated axis manager for manual control and readout, virtual execution of the PLC and automatic memory management effectively increases programming quality and efficiency. Through MotionPAC, PLC and .NET programmers can collaborate seamlessly to deploy machine control applications. MotionPAC comes with standard fieldbuses, high-end data acquisition and drive I/O, which can also be shared with applications by Name.

Leave a Reply

You must be logged in to post a comment.