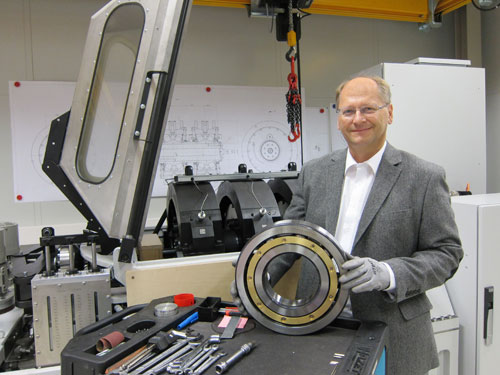

NKE Austria GmbH has finished the commissioning of a new test rig for medium sized rolling bearings. To illustrate the size of the test setup, Austrian bearing manufacturer NKE exhibited the test rig’s shaft complete with test bearings at this year’s Hannover Fair, before installing it in the new test rig. With the radial-axial test rig RAX380 for bearings with an outer diameter of up to 380 mm NKE is now capable of testing the running characteristics of bearings under varying test conditions and loads, speeds, lubrication conditions and temperatures. The new rig will be used to test standard bearings as well as custom and application-specific bearings.

At its headquarters in Steyr NKE operates its own test centre, which, in addition to the new RAX380 test rig for bearings of up to 380 mm, houses an RAX160 rig for testing bearings with up to 160 mm outer diameter. The test rigs yield valuable data about the tested bearings, such as their operating characteristics, wear and frictional behaviour and noise generation. In addition they allow to test the service life under the set operating conditions.

At its Steyr factory NKE manufactures components for bearings from 200 mm to 800 mm diameter. The quality and geometry of each component are tested both during and after production. Once assembled, bearing samples are subjected to function testing on the test rigs to determine their running characteristics and the interplay of their components. The running characteristics are mapped under defined load conditions with various radial and axial forces, speeds, lubricant temperatures and lubricant flow rates applied at each load level. Measured are the total frictional torque, vibration and the temperature rise on inner and outer race.

These long-term tests can be run at constant load or with variable load levels. To obtain statistically significant results at least five test runs under the same conditions are required. Because each of these test runs can take more than a thousand hours, durability testing with only one test rig can never be a routine operation.

In addition to the new and existing test rigs for bearings with an outer diameter of up to 380 mm and 160 mm respectively, NKE’s test centre boasts a range of other equipment for materials, dimensional and function testing: spectrometers and hardness testers for material testing, height gauge, form and roughness gauges, a 3D CNC measuring machine, roundness and surface testers, a dimension measuring station for large bearings as well as vibration and noise testing equipment.

NKE produces standard and special bearings for all industrial applications. Engineering, product development, production and final processing of components, modular assembly, quality assurance, logistics, sales and marketing – are centralised at NKE’s headquarters in Steyr, Austria. The factory in Steyr is certified to ISO 9001:2008, ISO 14001:2004 and OHSAS 18001. Its wide range of standard bearings is available from stock or at short production lead-times. NKE also provides tailored products and solutions. In addition to product development and application engineering NKE provides a full range of technical, consulting, documentation and training services. NKE’s products are distributed through 18 international representative offices and more than 240 distribution outlets in 60 countries.

Additional information about NKE test rig RAX380

Technical specifications:

- Speed: up to 4500 r.p.m.

- Radial test load: up to 250 kN

- Axial test load: up to 75 kN

- Drive: asynchronous 35 kW servomotor

- Oil temperature: up to 120 °C

- Test mode: automatic load spectrum or individual stages

- Lubrication and cooling: oil or grease

- Lubricant flow rate: up to 12 l/min per test bearing (separate circuits)

Measured variables:

- Temperature:

- Inner race

- Outer race

- Lubricant infeed

- Lubricant discharge

- Oil sump

- Torque

- Speed

- Radial and axial test load

- Cage speed, cage slippage, roller set slippage

- Oil pressure

- Oil quantities per bearing

- Vibration

Possible test bearings:

- Cylindrical roller bearings, deep groove ball bearings, taper roller bearings, angular contact ball bearings, spherical roller bearings, etc.

- Single-row, double-row and paired bearings

- Grease or oil-lubricated bearings

- Inner diameter: from 50 to 240 mm

- Outside diameter: up to 380 mm

Possible tests:

- Running characteristics

- Service life

NKE Bearings

www.nke.at

Leave a Reply

You must be logged in to post a comment.