By Michael Jermann, Assistant Editor

With gas prices and global temperatures rising, people are starting to take a closer look at harnessing the renewable energy of Mother Nature. Wind power is one of the fastest growing methods of energy generation. But in order to generate power efficiently, wind turbines must operate as smoothly and reliably as possible. Any fault in the motion of a turbine can cause excessive wear on components and increased maintenance costs. There are numerous bearing applications in a wind turbine and all must be able to withstand the harsh environments that these systems can encounter while maintaining the smooth motion needed to generate power.

Black oxide bearings from SKF address these issues by adding a special coating to the bearing that can be specified for all types of critical bearings in wind turbine systems to help promote higher reliability against widely varying temperatures, speeds, and loads and to resist contaminants, moisture, and chemicals that otherwise could limit bearing lifecycles and increase costs of turbine operation and maintenance.

The black oxidation surface treatment is applied to a bearing’s rings and rollers. The process – involving a chemical reaction at the surface layer of the bearing steel – is performed in an alkaline aqueous salt solution at defined temperatures. Up to 15 different immersion steps create a thin, dark black surface layer delivering a significant performance upgrade for the broad range of bearing types and sizes in wind turbines (up to 2.2 m in diameter and up to 1,000 kg per individual bearing component).

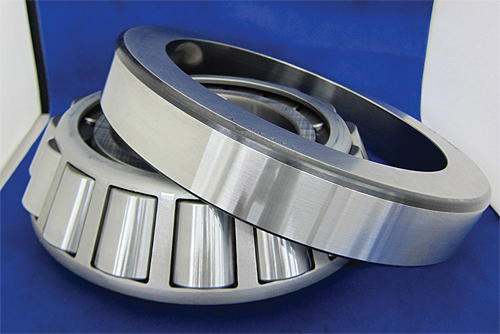

With global demands for energy growing, wind turbines have had to grow larger as well in order to generate the desired power. In response to these needs, NSK has developed large sized roller bearings that provide a high level of reliability through a combination of material developed by NSK and special heat treatment technology. The chemical composition of the bearing material delays hydrogen permeation and white structure change, while the heat treatment delays the occurrence and propagation of cracks, which could lead to flaking.

Hydroelectric applications are another promising source of renewable energy that benefits from bearings. The bearings used in hydroelectric turbines must be able to withstand a great deal of wear and be resistant to corrosion. The GGB-CSM and GGB-CBM series of bearings from GGB Bearing Technology suit such an application. Its GGB-CSM series is made of solid material, and its bimetal GGB-CBM series features sliding layers sintered onto metallic backings. Both are self-lubricating and provide high load capacity, a broad temperature range and corrosion resistance. The GGB-CSM and GGB-CBM bearing materials are manufactured using a powder metallurgy process to produce a metallic matrix with homogeneously distributed solid lubricant (graphite, MoS2), which forms a lubricant film with the bearings’ motion.

Oil remains, however, an important product in the modern world and extracting it can be a laborious and dangerous task. There are countless machines and devices needed to extract oil, but the crown block and traveling block are some of the most vital components on an oil rig. The crown block is a device that sits on a steel platform located at the top of the rig. The crown block consists of a series of pulleys and steel cables, or sheaves that work in conjunction with a similar device called the traveling block. The sheaves serve as drilling lines and pass through the traveling block below to connect to the rig’s hoisting drum. As the cables pass over the pulleys in one direction, they cause the oil drum to descend into the ground. When the cables pass over the pulleys in the other direction, they cause the oil drum to rise back up, bringing oil up for collection.

The crown block is a high maintenance piece of equipment and must be re-lubricated regularly. The Timken Sheave Pac bearing assembly is designed to eliminate the need to re-grease the crown block or traveling block on oil rigs. It does so through its sealed-for-life sheave bearing assembly, which helps to increase safety for rig workers and reduce expensive downtime. The assembly is preset, pre-greased, assembled and sealed at the factory — eliminating the risk of improper bearing setting and contamination and reducing the potential for bearing damage. The Sheave Pac assembly easily interchanges with current industry-standard bearing assemblies and seals and requires no modification of the sheave bore.

SKF

www.skf.com

NSK

www.nsk.com

GGB Bearing Technology

www.ggbearings.com

Timken

www.timken.com

Leave a Reply

You must be logged in to post a comment.