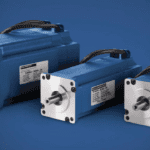

At the Automate Trade Show, Bison Gear and Engineering announces the launch of VFsync, a next-generation permanent magnet ac motor. Designed for today’s demanding machine drive applications, the new synchronous motors run at high efficiency with advanced variable frequency drives. The IP66/IP54 platform of three-phase motors range in power from 0.25 to 1.5 hp, and are supplied with swivel connectors and shielded cables to make installation trouble free. Popular frame sizes include IEC B14, sizes 71, 80 and 90 along with NEMA 56C mounting. The product line includes the new motors, quick connect cables and a market leading, programmable and networked VFD available in an IP 20 panel style or enclosed IP66 models.

The new motors were optimized with FEA software and then tooled with highly efficient internal permanent magnet style rotors. VFsync provides a compact footprint that is 56 % smaller and 63 % lighter than common three-phase induction motors. VFsync motors were designed to work seamlessly with Bison Gear & Engineering’s line of integral horsepower gear reducers to power even the most demanding applications with precise speed control.

Each frame size is available in either 230 or 460 V construction, and either TENV, TENV w/encoder or TEFC styles.

To learn more about VFsync, visit www.bisonvfsync.com.

Leave a Reply

You must be logged in to post a comment.