The sources of electrical noise can be varied, but one of the most common sources is from the high-frequency signals generated by variable frequency drives (VFDs.) This noise, called electromagnetic interference (EMI), can be picked up through cabling.

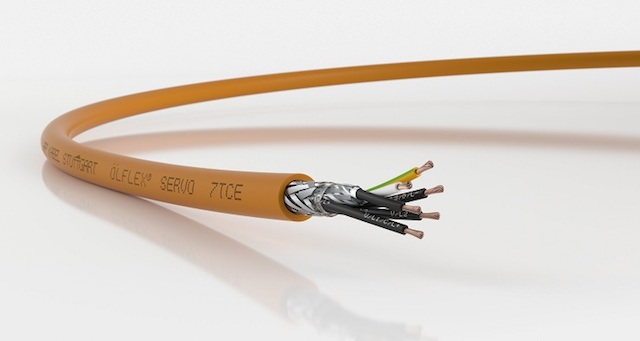

Cables themselves can be manufactured with special shielding to guard against EMI issues. The purpose of cable shielding is two-fold. One, it prevents electrical signals emitting from the cable, and two, it prevents other signals or electrical noise (EMI) from entering through the cable and disrupting other electrical equipment down the line. Shielded cable options include different types of shielding such as copper braiding, steel braiding, or combinations of these and other materials.

Another common way to minimize cable noise issues is to use twisted pair wires. This also reduces the amount of electromagnetic radiation of signals that could effect other equipment or unshielded cables nearby.

Optimizing the cable will go a long way toward eliminating noise issues. For instance, one simple fix (and what should always be a key design consideration) is shortening the length of cable used to connect equipment together. The longer a cable is, the more it acts as an antenna, making electrical noise problems worse.

Leave a Reply

You must be logged in to post a comment.