Decentralizing servo technology can lower costs in packaging and food and beverage applications. But centralized motion control has its advantages too. Sometimes the answer to which is better is neither one … but both.

By Dr. Arne Linder | Product Management • Kollmorgen

Decentralizing servo technology can bring machine and plant construction savings during installation. Two additional advantages are reduced cabinet heat loads and a drive architecture that is straightforward. But the question is which technology is better …

an integrated motor-drive system or a detached motor and drive?

As is often true, the answer to such a question is neither A or B, but C. Through mixed architectures and a large number of common features, both control types can coexist. In such cases, standard platforms are often the best approach.

Centralized architecture for motion

In contrast to horizontal conveying where decentralized servo drives are a common sight, centrally located servo drives still dominate the market for highly dynamic and precise motion control. Servo drives along with other control components, sometimes with a full-blown IPC, reside together in a control cabinet protected from the outside world. Connection to the motors is often in a star-shaped architecture, each having control and power cables. Because heat loss is centrally generated, effective air conditioning is needed in the cabinet.

The decentralized alternative

Decentralized servo technology follows the basic principal of moving the individual motor control from the central-control cabinet closer to the process. This architecture needs a robust design with a high degree of environmental protection.

The advantage lies particularly in terms of motor cabling. But other advantages include improved EMC-behavior and the widespread distribution of heat loss, reducing the cost or need for a central climate control cabinet.

Networking trends in machine building industry

With packaging machinery and machines for the food and beverage industry, the trend is moving away from meter-long cabinet walls, replacing these with small, self-protected units within the machine frame. The trend toward modular production facilities makes the distribution or combination of functions necessary.

Production equipment for these industries often consists of a main process and ancillary tasks. The ancillary tasks include a variety of compatible modules, for example, conveyor systems, sorters and handling units, which offer a path for easy machine expansion.

Practical experience also shows that a decentralized structure is advantageous, especially with spatially distributed single axes. In contrast, for machine modules for synchronized axes that are physically close together and centrally located, drives in a cabinet are generally the preferred structure.

Monetary savings in installation and mounting with decentralized topologies

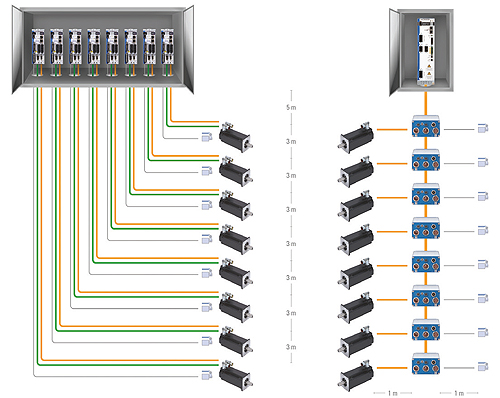

The savings potential of decentralized technology can be shown on an example metal forming machine with 8 axes. The first axis is located 5 m from the control cabinet. Each additional axis is located 3 m further. A centralized control system would have a central control cabinet housing the drives with each motor having separate shielded power and feedback cables adding up to 248 m of cable. A decentralized version would use a combination of a single power supply module and 8 decentralized servo controllers, reducing the cable requirement to 34 m.

The calculation: A single 5-m hybrid cable supplying power and field bus for axis control is connected between the power supply module and the first decentralized controller. A single hybrid cable 3 m long connects each additional drive for a total of 21 m. Because we assume that each motor is located 1 m away from each decentralized drive with a one-cable motor connection technology, only an additional 8 m of cable is required.

Overall, a decentralized system like this one reduced the cable requirements from 248 to 34 m, a savings of 86%. If the axes require additional I/O, the reduction in cabling is even more obvious. Instead of 372 m, only 42 m is needed, a corresponding savings of 89%.

Another benefit of the relocation of drives is the reduced need for air conditioning, providing savings for both the OEM and end user. As such, the control cabinet air conditioner can be smaller or completely eliminated, reducing costs for hardware and subsequent operations, ultimately increasing energy efficiency.

Increased design freedom with decentralized

Sample calculations show that decentralized servo technology saves space in combination with the single-cable connection technology between motor and controller. Benefits include smaller cable trays, lighter drag chains and more compactness for greater design freedom in the development of new machines. The bottom line is that this allows OEM plants to create new machines from already developed modules making the engineering more efficient.

Distributed drive technology as a hybrid

A second way to decentralize is with the use of a hybrid-integrated solution. These are combined motor and servo controller units without the need for external wiring. This so-called “piggyback” approach, though, has the disadvantage of drive derating with increased ambient temperature.

The higher the ambient temperature the more performance reduction occurs for the drive to self-protect from overheating. This relationship ensures that the motors must be larger than otherwise necessary to give the required performance within acceptable temperature limits for the electronics. Typical servo tasks such, as rapid acceleration and deceleration during positioning, can be especially difficult in the design of hybrid solutions due to the problem of effectively dissipating heat.

However, separating the motor and drive at this point prevents the inherent design-related derating. This solution provides the basis for smaller motors in combination with better energy efficiency. In addition, integrated combinations are usually focused on a single motor type, limiting flexibility in the machine design. In contrast, any brushless motor type can be connected to the decentralized servo drive.

An integration example

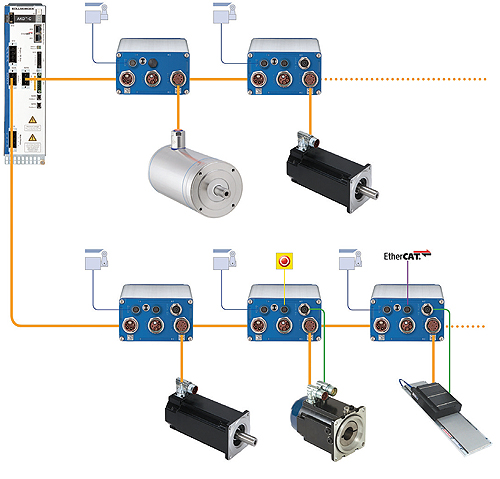

An example of servo drive technology for a food-processing machine helps clarify these relationships. The process begins with the cutting of sausage and cheese by a so-called slicer. The product is conveyed onto a belt. The process is not just a simple matter of conveying a sausage stack from point A to B, but to transport it as well-defined shingles. The need for highly dynamic single axis positioning system is clear.

The question now arises how to integrate the required motion control functions while maintaining central machine control. The slicer provides a good example because it represents a specific decentralized axis with a high power requirement that cannot be met with a decentralized drive. The primary objective from the manufacturing perspective is to harmonize highly diverse functional requirements for a wide combination of centralized and decentralized solutions.

The Kollmorgen AKD-N drive deliberately focuses on the use of a centralized AKD platform. It provides appropriate technology to allow the optimum selection of a motion solution for the performance task required, offered through the wide variety of compatible actuators.

Kollmorgen | www.kollmorgen.com

Leave a Reply

You must be logged in to post a comment.