by Bill Watson, Director of Application Engineering, Klüber Lubrication NA LP

Choosing the right lubricant for an industrial power-transmission design can be a tricky task, because industrial lubricants come in many varieties and formulations, and many industries require lubricants that adhere to specific regulations and standards. Here are some tips to make the selection easier.

For decades, lubricant suppliers have been developing and manufacturing specialty lubricants tailored to the requirements of industrial applications. There are general technical requirements that all lubricants must meet, including the reduction of friction and wear, protection against corrosion, dissipation of heat and sealing. But, depending on the operating conditions and manufacturing processes in the plant, lubricants may also be expected to provide a host of additional properties.

General purpose or synthetic lubricants?

One of the first questions a lubricant supplier should ask is if the equipment’s lubrication will be maintained at regular intervals or if it must be lubricated for life. The answer to this question helps determine whether the use of a general purpose lubricant or a synthetic specialty lubricant is more appropriate.

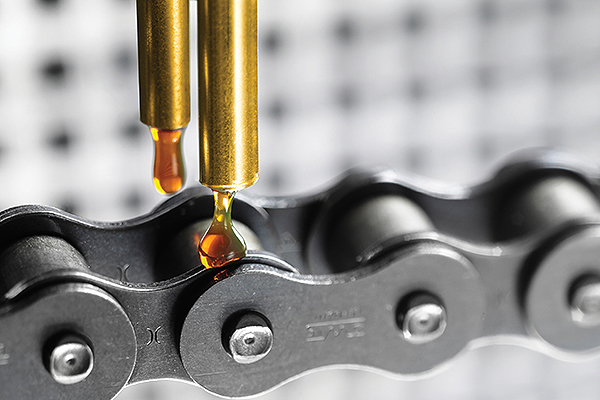

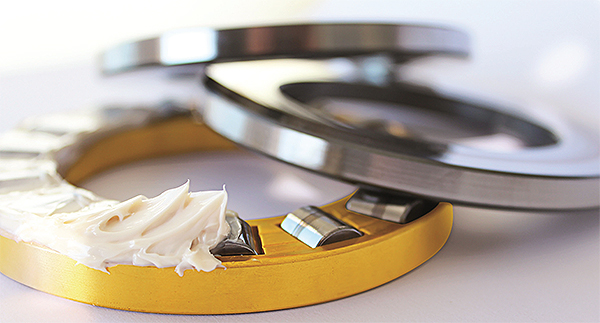

Oils, greases, pastes and waxes, and bonded coatings are the most common categories of industrial lubricants. Typically, an oil lubricant contains 95% base oil (most often mineral oils) and 5% additives. In contrast, greases consist of lubricating base oils that are mixed with a soap to form a solid structure. Pastes contain base oils, additives and solid lubricant particles. Finally, lubricating waxes consist of synthetic hydrocarbons, water and an emulsifying agent, which becomes fluid when a certain temperature level is exceeded.

The majority of oil lubricants, including many motor oils, are mineral oil distillates of crude oil (petroleum), while synthetic oil lubricants are also used. Synthetic oils such as polyalphaolefins (PAOs) or synthetic esters are produced artificially from other compounds. Because of this, the composition is quite different from petroleum oil. Their higher purity and uniformity provide for several enhanced properties, such as viscosity index, oxidation stability and color.

There are also semi-synthetic oils (also called synthetic blends), which are a blend of mineral and synthetic oil. This class of lubricants provides many of the benefits of synthetic oil at a fraction of the cost.

When synthetic oil is selected, it is generally to provide mechanical and chemical properties superior to those found in traditional mineral oils. When a manufacturer does not stock an appropriate synthetic lubricant with the performance features needed for a given power-transmission application, that design may necessitate a customized specialty or ‘optimized’ lubricant.

If the equipment will be regularly lubricated, synthetic or specialty lubricant designed to last for an extensive period of time is usually unnecessary. In this case, the lubricant needs only to meet basic performance standards and be replenished regularly.

On the other hand, if equipment is lubricated for life, synthetic base oils are often recommended for their many benefits:

• Low and high-temperature viscosity performance

• Decreased evaporative loss

• Reduced friction and reduced wear

• Improved efficiency

• Chemical stability and resistance to oil-sludge problems

• Extended drain intervals

Despite their many benefits, synthetic lubricants are also known for one distinct disadvantage of cost. But the cost may be mitigated by extended change intervals, as synthetic and specialty lubricants can last five times longer or more than non-synthetic lubricants when a high-quality base oil is used.

Factors that influence selection

The key requirement for selecting the proper lubricant is the base oil viscosity. In order to select the appropriate viscosity, the lubricant supplier will need to gather key information about the application at hand:

• Axis operating speed (variable or fixed)

• Specific type of friction (such as sliding or rolling)

• Load and environmental conditions

• Industry standards

For example, some lubricants such as PAG (polyalkylene glycol) oils are good for sliding friction, but are unsuitable for rolling friction. Likewise, PAO oils are used for rolling friction and can handle some sliding friction, whereas silicon and PFPE lubricants are typically used for extremely high temperatures.

Common mistakes in lubricating power-transmission components

During the information-gathering stage, equipment owners often make the mistake of overlooking some basic application details which can have a significant impact on the resulting lubricant’s performance. It is important to provide as much information as possible and to be specific, as this will help the design-engineering team and supplier identify the lubricant best suited to the task.

Another common mistake equipment owners make is choosing a lubricant based solely on price. Admittedly, there is a vast difference in the price of a synthetic or specialty lubricant and a general purpose lubricant. Some synthetic or specialty lubricants are 50 to 500% more expensive than general-purpose lubricants, but the price per kilogram should not be the only determining factor in selection.

Additional factors to take into consideration are:

• Reduced operating costs resulting from less downtime

• Improved labor utilization (as there’s less time required for re-lubrication and maintenance)

• Measurable energy savings and increased output

Often, when a supplier makes a lubricant recommendation for a particular application, and that application is successful, the customer wants to use the same lubricant in another application. Unfortunately, this is typically not an option. Remember, every application is different, and while one lubricant may work well for a ball bearing application, it likely will not provide the same performance for a different bearing application.

Ultimately, the first step in choosing the right lubricant is choosing the right lubricant supplier. Look for a supplier to provide quality documentation and detailed test data that demonstrate the consistency and quality of the product being recommended. A reputable supplier will spend time educating design teams so they can make qualified decisions about lubricating equipment.

Klüber Lubrication

www.klueber.com

Leave a Reply

You must be logged in to post a comment.