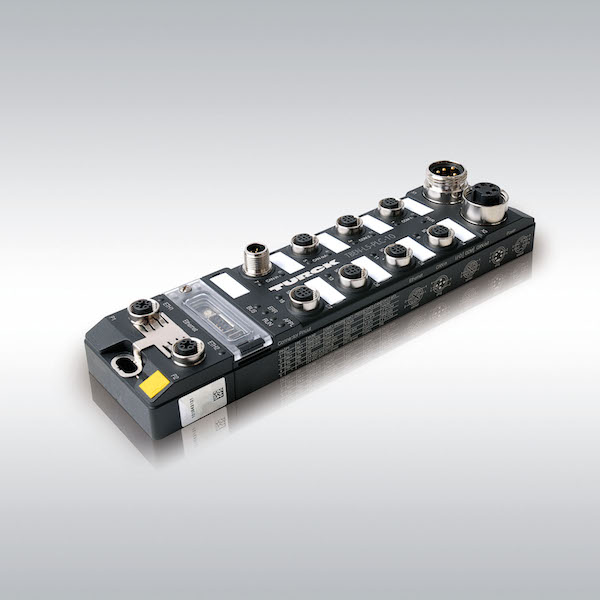

Turck’s new TBEN-PLC CODESYS 3 compact IP67 PLC is aimed at controlling small or modular machines. Thanks to its robust housing and high degree of environmental protection, the TBEN-PLC can operate directly on-machine, enabling the implementation of machine control without the need for a control cabinet. Using machine automation concepts and the use of pre-assembled cordsets reduce the cabling effort and simplify installation.

The wide variety of fieldbus communication protocols supported underlines the flexibility of the new TBEN-PLC; when used as a master/scanner, the device supports the industrial Ethernet protocols Profinet, EtherNet/IP and Modbus TCP, as well as Modbus RTU, CANopen and SAE J1939.

The TBEN-PLC can also be used as a remote I/O device for Profinet, EtherNet/IP, Modbus TCP, Modbus RTU and CANopen networks, enabling use as a protocol converter or gateway. For example, the controller can function as a CANopen manager for a machine module and connect this local network to a higher level system communicating over Profinet. As part of the increasing digitization of industry, this enables existing machine controls to be integrated into modern closely networked, highly flexible production systems.

Two onboard serial ports can also be used to integrate RS-232/485 serial devices. The device provides eight configurable discrete I/O channels for the direct connection of sensors and actuators. When combined with Turck’s fieldbus technology products with IP67 protection, comprehensive machine control including safety technology can be completely implemented without the need for a control cabinet.

For more information, visit www.turck.com.

Leave a Reply

You must be logged in to post a comment.