MILE stands for “maxon’s Inductive Little Encoder.” The operating principle is based on the measurement of high-frequency inductive fields, which generate Eddy currents in an electrically conductive target disk. The advantages of a high-frequency inductive measuring method in comparison with classic encoders are:

MILE stands for “maxon’s Inductive Little Encoder.” The operating principle is based on the measurement of high-frequency inductive fields, which generate Eddy currents in an electrically conductive target disk. The advantages of a high-frequency inductive measuring method in comparison with classic encoders are:

- High robustness against dust or oil vapors. This means that no additional protective measures, such as covers, are necessary.

- High speed.

- High resistance to interference pulses (for example resulting from PWM controllers or motor magnets).

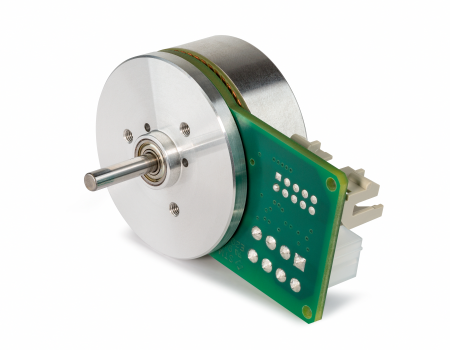

These properties make flat motors with MILE encoders an ideal solution for positioning tasks or high‑precision speed control. A significant advantage is provided by the small size of the encoder: the encoder disappears almost invisibly into the motor.

This system has been integrated into flat motors for two years. A new type has been added to the portfolio and there are now three performance classes available: motors with 45 mm diameter provide 30 to 70 W, depending on the length (between 15 and 28.4 mm). These drive units can be used both for high speeds of up to 10,000 rpm, and for direct drive with a continuous torque of up to 130 mNm. If required, the motor can be combined with a GS 45 spur gearhead or a GP 42 C high-torque planetary gearhead. The offer is also includes the ESCON servo amplifiers and EPOS2 positioning motor controllers.

The larger 90 W flat brushless motor (EC 90 flat) is now available with eight different impulse counts with up to 6400 counts per turn. Newly available versions of the EC 90 flat MILE encoder come with binary resolution. Binary resolution has the advantage that digital controllers can be manufactured with simpler processors, and thus with faster commands.

Versatility, power and robustness are the key characteristics of maxon’s flat motor series.

The various possible combinations of the brushless motors (BLDC) make them suitable for use in many different fields of application. The user is free to decide whether the main focus should be on a high continuous torque rating, positioning tasks with high dynamics and repetition accuracy or on robustness and resistance to external influences. Plus, due to its flat construction, the drive is ideal for use in narrow spaces.

Leave a Reply

You must be logged in to post a comment.