Edge computing and greater connectivity are some of the key trends controller manufacturers are seeing in their industry. Here’s what else they told us they’re seeing in the way of tech trends.

With respect to the IoT and IIoT, what kinds of capabilities do your components or engineered designs incorporate to support functions related to fog computing on local networks?

Lee Cheung

Product Marketing Engineer II (Controller/Visualization)

Mitsubishi Electric Automation, Inc.

Our iQ-F and iQ-R controllers feature a built-in web server that allows users to access status information, diagnostics, error and operation history from any connected device with a web browser. Advanced GOT2000 HMIs with GOT Mobile functionality offer even more capabilities with web pages that can be beautifully designed with simple drag and drop operation. GOT Mobile is easily configured even without any IT or web technologies knowledge, and can also serve up work instructions, manuals, and troubleshooting videos. Additionally, iQ-R controllers and advanced GOT2000 HMIs can deliver factory floor data directly to upper level IT systems databases.

Mike Chen

Director of Automation Center Americas

Omron Automation Americas

We’ve debuted our latest Sysmac AI Controller as an Edge based controller with machine learning engine embedded. To Omron, Edge is literally inside a machine, with direct access to data values being collected within the machine controller processing time. Data is analyzed within the machine and utilized within the user program without any data needing to go up into the local Fog or remote Cloud based IT infrastructure. We give our customers the option to connect their machine to Fog level SCADA software, in-house custom software solutions or long-term historian databases, but those systems are not required for high-speed high-accuracy anomaly detection on process data to be used for equipment maintenance or productivity optimization. Omron sells a robust line of Industrial PCs that reside on local Fog level networks that can run Omron InduSoft SCADA software, or other Windows/Linux based applications for visualization or batch data analysis.

Rodney Rusk

i4.0 Business Leader

Bosch Rexroth Corporation

Fog or Edge computing is common both in our Bosch manufacturing methodology as well as an integral part of many of the connected solutions that we adopt. Like many companies, we jealously guard our data and our knowledge know-how. Thus Fog computing is one methodology that helps us to optimize.

Looking at this from three viewpoints, we find ways to merge technology into a holistic plant ecosystem that feeds the necessary data into our Edge devices and our cloud-based resources.

At the top level, Fog (or Edge) computing to drive localized data analysis, condition monitoring and helping to drive machine learning. Within this sphere we work with such Bosch products as our Nexeed Production Performance Manager, Nexeed Production Quality Manager and Improvidus OEE analysis tools.

In the middle level, we network these tools to smart devices on our manufacturing floor to not only empower our associates with up to date real-time information, but allow for localized data comparisons. One example here would be the utilization of the Active Cockpit in our production rally/meeting areas. Using this tool, we can look at performance from individual machines, compare data sets, set priorities, capture decisions and respond to the needs of our production environment quicker.

Moving down to the lowest level, the actual machine level, by using smart devices such as our MTX CNC controls; our PRC7000 Adaptive Welding Controller or our IoT Gateway devices, we can pull data up through the new or older system to drive continuous improvement. In the case of the PRC7000 Adaptive Welding Controller, we can make-real time decisions to adjust the current voltage being applied to the welding operation and optimize consistent weld spots while reducing material losses.

What edge devices do you supply or support to allow for use of feedback signals or distributed motion control?

Rodney Rusk

Bosch Rexroth Corporation

The Bosch Rexroth and Bosch portfolio of products is quite expansive in the amount of manufacturing technology solutions that have feedback capabilities or motion controls resident on the devices. These pieces of equipment represent one example of i4.0 ready products that we produce for the external market and use extensively in our own manufacturing operations.

For example, the IndraDrive XLC combines the performance of Bosch Rexroth drives with embedded logic capability on-board. The product allows for advanced PLC programming using state-of-the-art PLC kernel, IndraLogic 2G, integrated homogeneously into the IndraWorks software tool and the multitasking runtime system. With its motion control functionality, the XLC handles machine applications ranging from simple point-to-point motion to the synchronization of multiple axes that use Rexroth’s FlexProfile to integrate complex motion sequences.

Another example would be the Bosch Connected Industrial Sensor Solution (CISS). The CISS is a multi-sensor device detecting acceleration and vibration as well as environmental conditions. The robust housing and the small outline makes it perfectly suitable for industrial retrofit applications such as condition monitoring and predictive maintenance. Configuring the device lets customers address a broad variety of use cases by interpreting the sensor data by smart algorithms from eight possible inputs such as acceleration, temperature, vibration and humidity.

Mike Chen

Omron Automation Americas

Our latest Sysmac AI Controller is an Edge based controller with a machine learning engine embedded as well as motion control. We give our customers the option to connect their machine to Fog level SCADA software, in-house custom software solutions or long-term historian databases, but those systems are not required for high-speed high-accuracy anomaly detection on process data to be used for equipment maintenance or productivity optimization.

Describe what you’re seeing in time-sensitive networking (TSN) and its application in motion applications.

Mike Chen

Omron Automation Americas

All Omron motion control capabilities have been standardized on the EtherCAT open network standard, as well as MACRO for specialized OEM applications. Using these high-performance deterministic network architectures, multiple motion devices can be synchronized to create complex electronically coordinated motion profiles, completely re-programmable and simulatable with direct control over torque, acceleration, deceleration, and jerk.

Rodney Rusk

Bosch Rexroth Corporation

Given the strong position of Bosch in the on-board vehicle product segment and the need for time-sensitive networking, the company has a long history as an industry leader. This includes all three areas of time synchronization, scheduling and fault tolerances. Looking back, we can see the development and implementation of early CAN-BUS solutions within these on-board vehicles by Bosch, for example in airbag deployment systems.

One of those areas was the early adoption of CAN-BUS within the Bosch Rexroth DC Tightening Systems, Platform 200 and 220, to provide rapid transmission of torque control data from the DC Tools installed on the line, back to the control panel and line management system. Today, when we look at the current generation of DC Tightening Tools from Bosch Rexroth, we find a high sensitivity to TSN and the improved transmission speeds that have resulted in the Platform 350 and now the NEXO Cordless DC Tool. The ability to provide time-sensitive feedback in an on-going assembly process is critical when dealing with minimal variation windows on safety critical applications like seat secure or restraint installations.

Other examples of our experience in the TNS area can be seen in the full complement of our Controls Product Lines, whether we look at the MTX CNC, the IndraDrive Mi or the MLC PLC products. In each case the use of synchronization modes such as velocity and phase synchronization or standardized motion profile functionality that is built in to the systems have all become second nature to our development teams.

In other areas, when fast absolute position of linear technology applications are required (+/- 4µm/m), such as when small rail deviation needs to be combined with multi-axis interpolation we look at our IMS-A line (Integrated Measuring System). These types of products allow us world-class accuracy of position and allows us to communicate over interfaces, such as Hiperface, SSI and DRIVE-CLiQ.

How does your company ensure interoperability between its offerings and product families?

Lee Cheung

Mitsubishi Electric Automation, Inc.

Mitsubishi Electric uses a rigorous design and quality review process that includes testing to ensure seamless integration between product offerings. We are uniquely able to maintain this strict level of control because we design and manufacture our own products. This also guarantees that the latest software versions are always compatible even with older hardware regardless of the firmware version, which saves end users and technical support staff a lot of headache.

Mike Chen

Omron Automation Americas

Omron has standardized on open networks such as EtherNet/IP and EtherCAT to ensure the broadest interoperability with different automation devices, while still maintaining the high-performance that our customers expect. Between our own product families, Omron has created a single Integrated Development Environment (IDE) which provides a single interface for configuration, programming, commissioning, and troubleshooting across our core automation technologies: logic, motion, vision, safety, robotics, visualization, and enterprise connectivity.

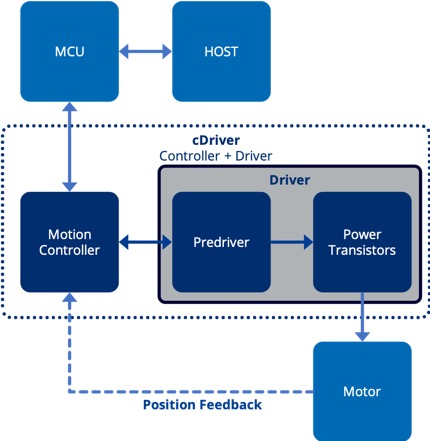

Jonas Proeger

Trinamic Motion Control

All of our products use the same protocols and interfaces, especially Trinamic’s own TMCL protocol. One of the results is that you can get any evaluation board you want and connect them together using Trinamic’s modular evaluation system. In addition, our components always follow the same partitioning between hardware and software. We equip them with industry-standard interfaces such as SPI, Step/Direction and standard encoder interfaces. A typical setup consists of:

- Microcontroller (not Trinamic product)

- Motion control IC, that generates ramps and commands current or target position via SPI

- Current control part, typically integrated in the motor driver, that generates a PWM-scheme

- The actual motor driver

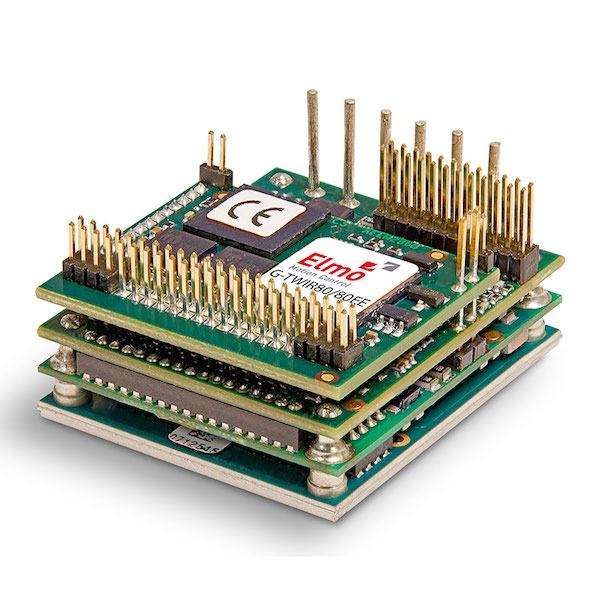

Tomer Goldenberg

Elmo Motion Control

Interoperability of Elmo Motion Control’s servodrives and multi-axis controllers is guaranteed through adequate networking communication. EtherCAT implementation ‘by the book’ is mandatory not only to assure interoperability between Elmo products, but also in order to interoperate with third-party devices. Ensuring high confidence levels of interoperability in terms of fieldbus communication is a result of ongoing efforts to follow strict industry regulations set forth by the EtherCAT Technology Group (ETG). Elmo has built an in-house lab with hundreds of I/Os and third-party devices with which it continuously tests every version of its products.

Further, regular delegations from Elmo’s R&D team visit ETG for their European Plug-Fest events, of which the goal is to assure interoperability with other EtherCAT communication devices in the market.

Rodney Rusk

Bosch Rexroth Corporation

Interoperability is one of the great challenges for both the provider and user of manufacturing technology. From our viewpoint, this is best served by not focusing on the individual product, but focusing on the ability of any products to be as scalable, flexible and open to as many “systems” as possible. Thus we try hard not to rely on one type of industrial protocol, for example, and we work diligently to make our products as compatible with non-Bosch solutions.

On a more practical day-to-day level, especially on the manufacturing floor, we have developed solutions that empower the users to bridge technology differences and try to meet the user where they are. For example, the use of our IoT Gateway device, allows us to help bridge the gap between older equipment and pull data into useful analysis tools; and our Open Core Engineering (OCE) software lets the machine programmer program in the scientific language that they are most comfortable with.

Finally at the higher software level, we have taken many of our stand-alone software solutions and have been unifying them under the Nexeed Suite of Software, creating a stackable solution set where we are actively pulling in various software modules (such as our Track & Trace and Intra-Logistics packages). Of course, this is an on-going development that has no real end date; we simply apply our philosophy and drive toward increase interoperability to meet the needs of our clients.

What value-add services (or in-house engineering support) have you provided to an OEM or other customer during the last 12 months?

Todd Mason-Darnell, Ph.D.

Marketing Manager – Services & Safety

Omron Automation Americas

Omron provides automation and safety systems engineering and integration services to OEMs and end users. Combining our in-house engineering resources with a network of certified partners, we support automation and safety engineering at all stages of the machine life cycle.

Jonas Proeger

Trinamic Motion Control

Our business model is selling standard products. Nevertheless, we offer engineering support for key accounts and also design customized board level solutions, if this helps the customer to achieve their goal faster. A typical application is for the development we did for a customer specialized on motorized prosthetics, where we developed a servo drive for the knee joint in an artificial limb. The customer provided the AI algorithms for the kinematics and interpreting the patients’ movements, while we provide the electronics and the software for the motion control.

What are your thoughts on new trends in wireless connectivity and technologies related to wireless power transfer for industrial applications and machine designs?

Lee Cheung

Mitsubishi Electric Automation, Inc.

We see wireless connectivity being adopted in particular with the use of GOT Mobile functionality on advanced GOT2000 HMIs. This lets maintenance engineers remotely monitor machine status and gives them the flexibility to move around a machine while checking documentation when troubleshooting. Production managers also benefit from being able to monitor production status to ensure that production targets are being met.

Mike Chen

Omron Automation Americas

Omron puts 7% of its annual revenue back into R&D across many technology sectors that is then applied into industrial automation, healthcare, mobility, energy management, and other business units. At this point, the Omron Industrial Automation business has not yet productized any wireless power transfer devices, but has released battery-less wireless push-buttons and wireless Ethernet communication adapters that are available according to regional regulatory compliance.

Tell us about any selector, sizing, or sales software you use or offer to customers and how these tools are changing how design engineering is done.

Lee Cheung

Mitsubishi Electric Automation, Inc.

Selection tools that we provide for controller products help streamline the process for creating a bill of materials. These tools check to make sure that the system configuration is valid and even take out the tedious work of calculating power requirements.

Mike Chen

Omron Automation Americas

Omron has recently opened up its internal cloud-based Bill Of Material (BOM) generation tool to our customers, abbreviated ONSeT – Omron Navigated Selection Tool. This tool lets design engineers peruse and select Omron products by feature and application needs, identify optional or required accessories, and then add-in their non-Omron line items for a single point proposal generator.

Leave a Reply

You must be logged in to post a comment.