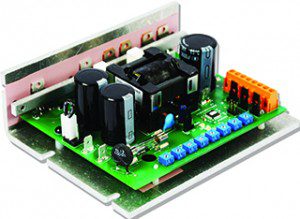

American Control Electronics (ACE) announces the DCH Series Actuator Control, combining an AC to DC switching power supply with a regenerative PWM drive to create an all-in-one solution that saves space, reduces setup time and lowers costs. The DCH Series is ideal for applications requiring control of 12 or 24 VDC motors when only 115 or 230 VAC power is available. With an isolated front end, this series is compatible with a 0-5 or 0-10 VDC analog from any PLC. (With an 8-bit onboard microprocessor, the DCH Series can be customized in many applications to even replace a PLC.) The series also provides an alternative to the common practice of using higher-voltage controls with the output voltage turned down, which results in current spikes that are tough on the motor and reduce brush life.

American Control Electronics (ACE) announces the DCH Series Actuator Control, combining an AC to DC switching power supply with a regenerative PWM drive to create an all-in-one solution that saves space, reduces setup time and lowers costs. The DCH Series is ideal for applications requiring control of 12 or 24 VDC motors when only 115 or 230 VAC power is available. With an isolated front end, this series is compatible with a 0-5 or 0-10 VDC analog from any PLC. (With an 8-bit onboard microprocessor, the DCH Series can be customized in many applications to even replace a PLC.) The series also provides an alternative to the common practice of using higher-voltage controls with the output voltage turned down, which results in current spikes that are tough on the motor and reduce brush life.

The DCH Series includes an industry standard microprocessor used on many of today’s popular PLCs. For OEMs using PLCs simply for the functionality of programming the same code repetitively, ACE can install that code directly on the HTL control, eliminating the need for the PLC entirely. A modified option allows for linear positioning control of actuators to within 1/1000th of commanded stroke length with the use of feedback resistors, for more precision than many positioning applications require at a lower cost than positioning servo systems. Standard variations for the DCH Series include options for torque, cycling, or positioning control.

- Summary of key features of the DCH Series Actuator Control:

- Microprocessor Based: Easily programmable for OEMs

- Standard I/O: 1 analog, 4 digital – custom configurations available

- All-in-One Package: Combines a custom regen-capable switching power supply with a low voltage drive True Low Voltage Output: Allows control over low voltage motors without the negative effects of current spikes or a large BUS voltage associated with typical 115/230 VAC SCR and PWM controls

- 4Q Reversing: Delivers the ability to perform quick and contactorless braking and/or reversing-on-the-fly

- Isolated Logic: Allows floating or grounded 0 – 5 or 0 – 10 VDC signals Stopping Modes: Forward and reverse inhibits can be set for N.O. or N.C. to brake to a stop. Can be used for rapid starting and stopping Diagnostic LEDs: Power, Current Limit

American Control Electronics

amcntrl.com

Leave a Reply

You must be logged in to post a comment.