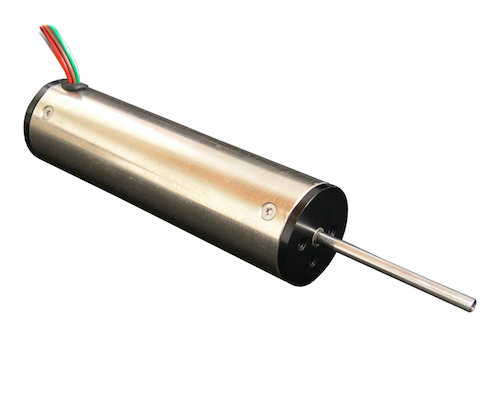

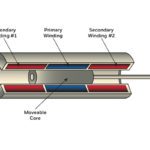

The SDLM-025-070-01-01 and SDLM-025-070-01-05 direct drive linear motors from Moticont, also known as electric cylinders, have built-in encoders, and feature high acceleration, high speed, high resolution, zero backlash, and zero cogging. These compact direct-drive linear motors with quiet linear plain bearings are just 1.00 in. (25.4 mm) in diameter and 2.75 in. (69.9 mm) long. Protected inside the motor housings are linear optical quadrature encoders that directly connect to the non-rotating shaft for the greatest possible accuracy.

Select only the degree of precision your application requires as the SDLM-025-070-01-01 has a resolution of 1.25 microns and the SDLM-025-070-01-05 has a resolution of 5.0 microns with a 10% savings in cost.

Each of these direct-drive linear motors has a stroke length of 0.500 in. (12.7 mm) and a continuous force rating of 22.2 oz (5.9 N) and peak force of 67.2 oz (18.7 N). Non-commutated, they feature direct coupling of the load or stage which eliminates backlash and allows for high acceleration/deceleration. Both ends of the motor and shaft ends are drilled and tapped for easy integration into new and existing applications. Some common applications include assembly, manufacturing, sorting, semiconductor handling, inspection, medical equipment and procedure tables, antenna positioning, dampers, door & valve actuators, agricultural equipment, and adjustable office furniture.

Inexpensive alternatives to hydraulic and pneumatic systems, these direct-drive linear actuators or electric cylinders are also available as a complete plug-and-play linear motion system with matching motion controllers.

For more information, visit www.moticont.com.

Leave a Reply

You must be logged in to post a comment.