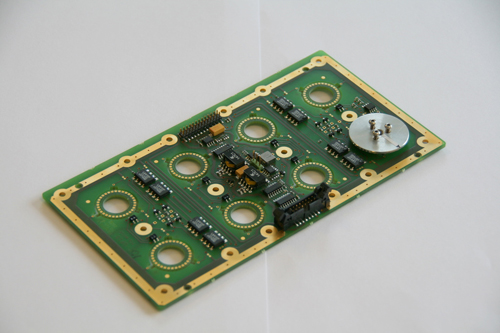

A new whitepaper is now available to help engineers take advantage of groundbreaking technology for movement in applications. Traditional design methods use PCBs as motor controllers with connections to a physical motor located somewhere in the vicinity of the card. “For building smaller, cheaper and better applications, we offer a patented new technology that allows you to build one or more motors directly onto the PCB itself. It significantly reduces application cost – and introduces a world of new design opportunities” explains Henrik Staehr-Olsen, CEO of the Danish company PCBMotor.

The whitepaper, available at http://www.pcbmotor.com, describes how, using standardized components and well established assembly techniques, you can use increase your profit margin:

• Reduce application size by integrating motor and all electronics into one printed circuit board.

• Reduce bill of materials – PCBMotor’s direct drive eliminates gears.

• Further eliminate cost by getting rid of screws, wires, connectors and manual assembly.

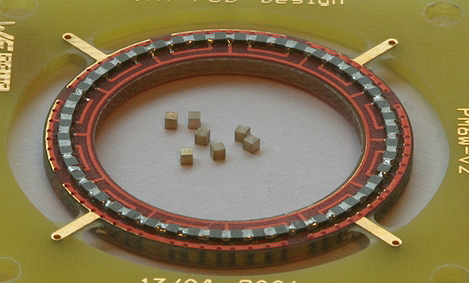

• Actuator components for the PCBMotor are SMD-mounted directly on the PCB.

• Increase your design options with the unique hollow and ultra slim form factor of the PCBMotor.

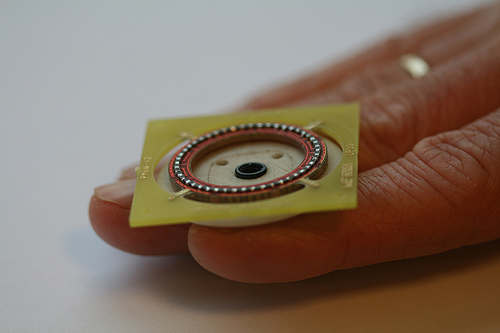

Technically speaking, the PCBmotor consists of two parts: (1) The stator, milled out of the PCB itself, holds the piezos/actuators and electrical connecting circuit (the PCB can also hold the driver) and (2) The rotor, pressed onto the surface of the stator, delivers the mechanical output. A travelling wave is generated over the stator surface, acting as a flexible ring to produce elliptical motion on the rotor interface. The elliptical motion of the contact surface propels the rotor and the connected drive-shaft.

1x1mm piezo ceramic components are mounted on PCB. Operation depends on friction between the moving rotor and stator as well as amplitude and quality of the wave travelling on the stator. The rotor can turn between 60 and 120 RPM with torque ranging from 1 Nmm to more than 70 Nmm depending on the stator’s diameter, number of piezo components and the rotor design and material.

Leave a Reply

You must be logged in to post a comment.