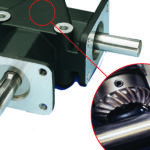

Now there’s a better way to mount components on motion control shafts while verifying the installation for quality purposes. It’s the ETP Express shaft-locking bushing that locks into position gears, pulleys, sprockets and other components in automated machinery.

Handling torque ranges from 34 to 12,538 ft-lb (46 to 17,000 Nm), these ETP Express shaft-locking bushings from Zero-Max ensure fast mounting, repositioning and phasing of the components to the shafts. Three key reasons make the ETP Express a superior shaft-locking device:

Fast Installation: Positions in seconds and can be readjusted hundreds of times just as quickly. No axial movement of the bushing or component along the keyless shaft during installation. Much faster installation than other mechanical bushings requiring multiple screws. An Allen wrench is all that is required to mount and lock ETP Express bushings into place. They have sealed, clean lines that resist debris collection and clean easily without any special maintenance.

Minimal Runout: ETP Express provides maximum concentricity with a solid and more precise connection between shaft and hub unlike conventional shaft locking bushings. Its hydraulic design gives even and full contact pressure around the circumference of the bushing. The bushing aligns precisely without axial movement as it is tightened.

Verifiable Installation: With single screw installation, ETP Express locks securely into position, making it a verifiable installation position for maintaining ISO procedures and quality maintenance records. One mounting screw equals one torque value. By comparison, most mechanical bushings require torqueing at multiple locations. With multiple screw mechanical bushings, torqueing at one location easily changes the result at an adjacent location with a loss of concentricity.

Available in 15 through 100 mm and various inch shaft sizes, ETP Express bushings are a great choice for new and retrofit applications particularly in automated machinery applications.

See the video demonstration below:

For complete information, go to www.zero-max.com.

Leave a Reply

You must be logged in to post a comment.