When selecting a stepper drive, certain features must be compatible with the motor and the drive for the system to function. These include the current output of the drive, whether it is for unipolar or bipolar stepper motors, its voltage output and its wattage or power rating. All of these factors matter for their own reasons and in combination. Additionally, other compatibility requirements may be the method of microstepping, if any, and the physical wiring requirements of the motor.

Current output: striking a balance

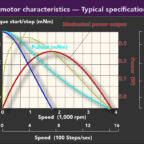

The current output from the driver is important because current affects how much torque a stepper motor can produce. Too little current and the stepper motor cannot operate at its rated torque levels. This can cause stalls and skips during operation. Too much current, on the other hand, can cause overheating which can lead to motor failure or overheating of other components in the system. A stepper drive, therefore, must be able to provide enough current to operate a stepper motor so that it provides all of its rated torque. However, it must not allow the stepper motor to draw too much current and overheat.

Voltage output: motor dictated

When selecting a stepper drive, keep in mind that different stepper motors are designed to work at different operating voltages. If the driver selected cannot supply the correct voltage to the motor, it is not compatible. For example, if the desired stepper motor requires 60 V DC to operate, yet the selected drive can only supply 40 V DC maximum, it cannot run that particular motor correctly. In the opposite direction, if the motor is not designed to handle more than, say, 50 V DC, and the selected drive has a voltage output of 100 V DC, this is also not a compatible setup. Such a situation may cause the motor to burn out or experience dangerous operating conditions, such as runaways.

Unipolar or bipolar depends on the motor

Recall that stepper motors come in two primary forms, unipolar and bipolar (read FAQ: What is a stepper drive and how do they work?). These terms refer to the windings in a stepper motor and how they connected to a controller. Make sure to match the drive type the motor type when considering windings. Some drives allow both methods of winding to be connected, others only permit one or the other. Additionally, some motors can operate as either unipolar or bipolar, by changing which wires connect to the drive, and others are not. Keep this in mind when checking if the desired drive and motor setup is compatible.

Power — Wattage ratings

A stepper motor has a certain power rating applied to it. Remember that in electromagnetic applications, such as stepper motors, the equation that determines wattage is W = V×A. Where V is volts and A is amps. As such the drive must supply the correct current and voltage levels for the stepper motor to draw the right amount of power. Note that this is not the same as the power output of the motor. This value is the power input to the motor. This value’s accuracy can help determine what portion of the total power use of a system is attributable to the motor.

Microstepping and other concerns

If the stepper motor is intended to for use with microstepping, ensure that the algorithm used by the controller, the drive and the motor are all compatible. Some methods are proprietary, and others are not, check with the manufacturer. Also, remember certain features of a motor may work using certain combinations of compatible options, but not others. Microstepping, for example, may only work when using bipolar connections for a particular combination.

For these reasons, it is always best to check with the manufacturer(s) of whatever combinations of stepper motors and drives are in use. Thorough checking of calculations and documentation is also good practice. For more information, read Parker Motion’s Step Drive and Motor Compatibility Chart.

Leave a Reply

You must be logged in to post a comment.