Inertia mismatch is the difference between the inertia of the system and inertia of the stepper motor. A large inertia mismatch is usually best avoided for machines run by stepper motors. One, the stepper motor itself has inertia it must overcome, in addition to the inertia of the system it drives. Two, friction further affects inertia, and three, having too much torque from an oversized stepper motor poses its own set of problems.

Inertia mismatch greatly affects how stepper motors operate. The motors cannot accelerate and decelerate rapidly with an extreme inertia mismatch. If they have sufficient torque, but an inertia mismatch is present, the load may not start or stop at the proper time or place. At its most extreme, inertia mismatch can cause skipped steps or non-functioning stepper motors … along with noise, vibration, and heat.

There are a few ways to handle inertia mismatch. One is simply to size and match motor and load and ensure that the load-to-rotor inertia ratio falls between 1:1 and 10:1 or close to it … with 3:1 being suitable for high-performance systems.

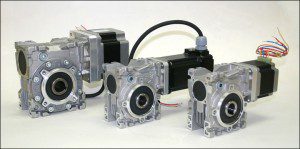

If for whatever reason this is not feasible, some techniques exist for handling excessive inertia mismatch. One approach is to drive the motor through long acceleration and deceleration periods so the motor doesn’t miss steps and nothing falls out of sync. One caveat: this degrades efficiency and throughput, because there’s more of a wait for getting to full speed and for coming to a complete shutdown. One fix is to use a properly designed gearhead on the motor. This can address inertia mismatches, though this introduces more design considerations and complexity.

For more information, read:

PDF download: Applying step motors successfully

Oriental Motor step-motor basics

Kollmorgen PDF: The significance of load to motor inertia mismatch

Leave a Reply

You must be logged in to post a comment.