Input/output (or I/O) is central to every PLC. I/O is the connection of the controller to the outside world and to the machine or process being controlled. Inputs to the PLC can be either voltages or currents representing physical variables or the status of devices such as switches, motors, or lights.

Inputs and outputs can be either digital or analog and I/O modules are available for the appropriate type of I/O. The use of analog or digital will depend on the input source and what type of output is needed.

For example, digital I/O can consist of devices that turn on or off, like switches or output devices like motors or relays. Analog I/O may include things like physical variables that vary in real time such as temperature, pressure, or speed, where the input devices would be, correspondingly, a temperature sensor or thermocouple, pressure sensor, and tachometer. In general, analog I/O requires more processing than digital I/O, so the more I/O the more processing and memory required to handle it. Typical analog signal ranges include industry standards such as 4-20 mA or 0-20 mA, and 0-5 V or 0-10 V.

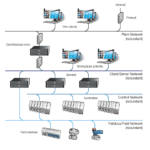

Another way to think of I/O is how it integrates with the PLC. Basically, I/O can be integrated or distributed. Examples of integrated I/O include modules that are integrated into a PLC chassis or on a rack-mounted system. In contrast, distributed I/O can be embedded in a machine and so is much closer to the process being monitored or controlled.

The most essential point about PLC I/O is to know the application requirements, which will determine what type of I/O is needed and how many I/O points the system requires. PLC manufacturers offer I/O expansion modules that can be added to the PLC to handle more and different types of I/O, which can change as the machine evolves to meet the changing demands of an application.

Leave a Reply

You must be logged in to post a comment.