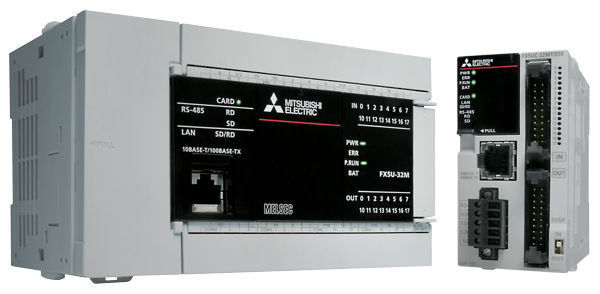

Programmable logic controllers, or PLCs, are computers that control automation and motion systems. They are real-time computers in which inputs must create outputs in limited time. They usually store programs that perform control algorithms in non-volatile memory or battery-backed memory. Using a PLC with a stepper drive allows control mechanisms to change using software control, rather than switches and manual rewiring. When using a PLC with a stepper drive, there are some unique aspects to the implementation.

A PLC is not the drive, as it cannot output voltages and currents required by the motor. Rather, the PLC outputs the control signals to the drive, which then outputs the voltages and currents. Thus, the line of control is from PLC to drive to the motor. Additionally, if operating closed loop, the PLC receives that feedback from the motor, encoders and sensors. This feedback can also be fed into the PLC’s software and make corrections as required during operation.

A PLC and a personal or desktop computer have much in common. Both have RAM, CPU, ROM, Firmware, and other similar components. However, PLCs are designed to be far more rugged and operable in industrial environments. While it is possible to use a desktop computer as a PLC, this is not usually done because consumer operating systems and computers are not rugged or responsive enough.

Engineers or computer scientists write the code that manages the drive and algorithms. This code runs on the PLC and keeps track of all operations and engineers can modify it in response to changed operating conditions. Drives connect to a PLC’s input-output ports. These are usually various connectors, both standardized, such as USB and EtherNet, and proprietary. Using PLCs connected to various other components allows stepper drives to integrate well into a system.

For more information, download the PDF: Three-Phase Switched Reluctance Motor Control with Encoder Using 56F805 Designer Reference Manual — by Peter Balazovic of Motorola.

Leave a Reply

You must be logged in to post a comment.