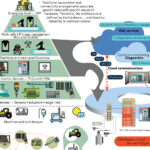

The Productivity Master, a modular demonstration system for personalized USB memory sticks from Festo, shows how automation technology will evolve along the value chain when combined with digitalization. The Productivity Master demonstration will be the centerpiece of the Festo exhibit at the upcoming Hannover Fair Digital Edition April 12-16.

Thanks to seamless connectivity, everything fits perfectly, from the mechanical and electrical systems to the intelligence. The Festo automation platform provides an integrated and practical system to link all Festo engineering tools, components, and solutions in hardware and software.

The demonstration shows how a plant can achieve a balance between mass production and individualization of a finished product. The electrical products, the axis mechanics, the electrics, and the software are planned as a complete automation platform with seamless connectivity. With this consistency, users save a lot of time in their machines and systems – from planning to commissioning – and gain process reliability because everything fits together – Industry 4.0 included.

Cloud-based concept

For example, the Productivity Master uses a cloud-based concept for registering and storing customer data complying with data protection regulations. This allows USB sticks to be produced with a personalized design as well as personalized data content. Customers could do this from home via the Internet without having to enter further data from other people on the supplier side.

Customers can use the same concept to reduce labor costs and coordinate the process from the home office. Festo’s IoT gateway securely connects the machine to the cloud so that operators cannot only retrieve production data from the cloud, but also access the machine’s diagnostic data, even if they are sitting hundreds of miles away in their home office.

Mask production and vaccines

The pandemic year 2020 revealed just such a contrast between mass production and individualization or small series production in the examples of mask production and vaccine research. The latter is more focused on precise data collection. For mass production, however, it is crucial to be able to use remote diagnostics and maintenance tools to maintain machine uptime as long as possible while protecting operator health.

“It doesn’t matter if the product weighs a few ounces or more than 200 pounds – being a technology-neutral company, Festo has the product range to do this,” explained Nigel Dawson, Head of Business Development Electric Automation at Festo. “While the Productivity Master features a mix of pneumatic and electric automation, from flow sensors to servo drives, from pneumatic slide units to electric Cartesian robots, it is the way these products are connected that enables true digitalization.”

Seamless connectivity

By leveraging industry-standard networks such as EtherCAT, OPC-UA, IO Link, and MQTT, Festo can create a seamless data stream from individual sensors to remote IO, servo drives, controllers, and the cloud. “This technology-neutral approach has a major impact on energy efficiency and sustainability. We call this ‘seamless connectivity,’” added Dawson.

The Productivity Master was designed in record time utilizing Festo’s state-of-the-art unified engineering environment which includes project planning capabilities and management of digital twins. This allows designers and developers to work collaboratively worldwide. With the Festo Handling Guide Online HGO, users select and dimension 2D or 3D gantries in just three steps. For quick and easy programming, configuration, and commissioning in a shared virtual environment, they use the Festo Automation Suite.

Digital Customer Journey

“Along the journey to digitalization, we enable customers to correctly and efficiently select and size products online, add them to a shopping cart in a seamless process, view pricing and delivery in real time, and track products throughout the supply chain,” said Dawson, describing this digital value chain. “With developments in artificial intelligence (AI), Festo is expanding concepts such as digital nameplates, digital twinning and, of course, AI-driven predictions of machine conditions for remote maintenance.”

Four fully connected stations

In a show setting, attendees create the production order at the first station by registering with their name and perhaps a picture. A QR code identifies the visitors at the machine. A vision sensor SBSI from Festo registers the visitor and starts the production order, followed by stock management. This mechatronic complete solution, made up among other things of a planar surface gantry EXCM in size 40 for fast picking and placing of the USB memory stick, offers all the options from stock management and workpiece handling to the cloud.

The USB memory stick is transported, printed, turned over, and then passed on. The work steps at the second station involve holding, moving, handling, rotating, positioning, and identifying the workpiece position as well as identifying, separating, gripping, and applying labels. Fast transfer to a label printer is carried out at station 3 by a highly dynamic linear gantry EXCT with dynamic servo motors EMMT-AS and servo drives CMMT-AS. The rotation functions are performed by electric rotary drives ERMH.

The process is completed in station 4, where files are uploaded to the USB memory stick. Station 4 operations include holding the workpiece, turning, and carefully positioning the cap and press-fitting delicate parts. This is done using the attractively priced electric cylinders EPCO and rotary drives ERMO.

The Festo general information number is 800-993-3786. For more information, visit www.festo.us.

Leave a Reply

You must be logged in to post a comment.