Recently I attended the annual Technology Days event at ABB Robotics’ North American headquarters and training center in Auburn Hills, MI. The two-day event spotlighted some new robot offerings from the company as well as a number of demonstrations and informative technical seminars. Demonstrations included applications in welding and cutting, packaging, material handling, as well as painting and machine tending among others

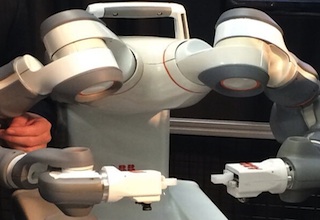

But perhaps what was most intriguing were glimpses into the future of robotics. One such glimpse came in seeing the company’s prototype Dual Arm Concept Robot (DACR) in action. Aimed at applications involving small parts assembly, such as in the consumer electronics industry, the robots would include two arms with flexible grippers and would locate parts visually using a camera.

The prototype robots come as portable units with a controller integrated into the torso. They can be carried around easily and mounted into workstations. The robot’s padded dual arms and low force output means that they can be used in situations where they can work side-by-side with human workers without the need for any additional safety measures, as is called for in other industrial robotic applications such as packaging or material handling which require added safety measures for work cells.

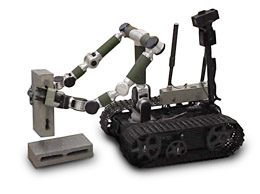

Other companies are experimenting with dual-arm robots as well. For instance, Epson introduced a similar concept robot last November at the International Robot Exhibition in Tokyo. Another company with a dual-arm robot is HDT Global, shown below lifting concrete blocks.

While robots can indeed be helpful in replacing humans in some high-risk applications such as in military uses and hazardous work areas, the more concerning trend may be the use of more robots in areas such as light assembly.

The implications are fairly clear; these robots are designed and built to look like and function like a human worker, using two arms to pick up small parts and assemble them in exactly the way a human worker would. The robots will replace some workers on assembly lines. And even though this is partly the age-old concern over the way automating certain tasks displaces human workers, with ever smarter and more human-like robots emerging on the scene, these just may be significantly different.

Should we be worried or should we welcome our new robotic coworkers? Tell us what you think.

Leave a Reply

You must be logged in to post a comment.