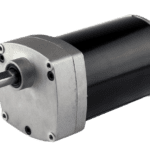

Bison Gear & Engineering Corp. has debuted its Bison Pull-Tight gear motor enclosure for demanding outdoor applications subjected to occasional underwater submersion. Originally designed for electric pool covers, the Pull-Tight has proven its exceptional durability in agriculture and many other environments exposed to harsh weather conditions, including flooding.

This innovative solution developed by the Bison team of more than 50 engineers in St. Charles, IL, received US Patent 10,320,259 for the design of the enclosure. The shell and fasteners are stainless steel and are enclosed by an extruded silicone sleeve that serves as the main gasket and protects the assembly from the environment. The silicon withstands heat generated by the motor. The aluminum and powder-coated end cap provides an enclosure for the termination, with space for capacitors, magnetic contactors, relays and other components — all protected from the outdoor environment.

For more information about the Bison Pull-Tight gear motor enclosure, visit www.bisongear.com.

Leave a Reply

You must be logged in to post a comment.