Graphite Metallizing Corporation (www.graphalloy.com) has unveiled their latest range of Tin Based Babbit GRAPHALLOY materials, which are FDA certified and are also offered in NSF certified grades for potable water.

These tin based babbit materials are also suitable for high temperature bearing applications up to 175°C (350°F) and can perform well as self-lubricating bearings in dry and submerged applications.

GRAPHALLOY, which is a graphite or metal alloy, provides various advantages. It effectively eliminates the need for oil or grease and is environmentally safe to use and machine. The elimination of liquid lubricants reduces maintenance and contamination.

Offering superior heat dissipation without melting or cold flow, GRAPHALLOY Tin Based Babbitt materials can also be used as a substitute for plastic. In low temperature applications, such as -400° F/-205° C, these new bearings of Graphite Metallizing Corporation solve lubrication issues caused the viscosity to oil and grease that commonly prevents proper operation of equipment.

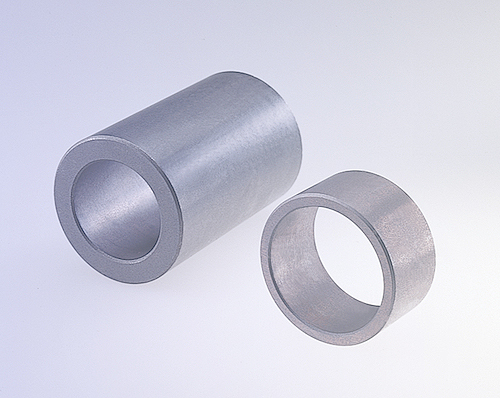

The all-new GRAPHALLOY Tin Based Babbitt offers all the necessary performance benefits of traditional babbit materials. Users need not worry of any environmental concerns since it can be safely used in food applications, drinking water applications and traditional low temperature applications. For new equipment design and the most challenging plant maintenance, GRAPHALLOY bushings and bearings provide the proven solution.

Aside from being self-lubricating, GRAPHALLOY materials are also impervious to extreme temperatures (from -400°F to +1000°F/-240°C to 535°C). Used in the manufacture of bearings, bushings and other for process and machinery equipment, GRAPHALLOY materials thrive in the most extreme environments where other competing bearings fail.

Leave a Reply

You must be logged in to post a comment.