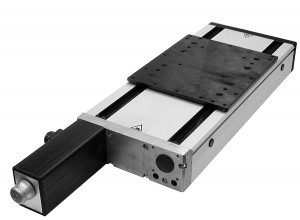

New Hyde Park, NY – Techno, Inc. Linear Motion Systems introduces the newly improved Heavy-Duty Slide 2, constructed from a single rigid aluminum extrusion profile and capable of handling heavy-cantilevered loads. The 225mm wide, modular design is available in travels from 122mm (4.8in.) to 2722mm (107.2in.) with a new wraparound motor mounting kit that allows for longer travel with shorter overall lengths. The Heavy-Duty Slide 2 is made to be extremely versatile with T-slots on three sides for easy mounting options.

The Heavy-Duty Slide 2 offers a wide stable base for use in assembly equipment and the ability to handle large cantilevered loads makes it ideal for a range of applications. The Slide 2 also uses Teflon lip seals so that the full length of travel is utilized and the interior components are guarded against contaminants.

All models are fit with four precision rails, four bearing blocks, home reference and end limit switches. Users can choose from inline or side-mounted stepper motors or servomotors. The 16mm anti-backlash ball screws are available in 2.5mm (0.1in.), 5mm (0.2in.), 10mm (0.4in.), and 20mm (0.8in.) leads. Complete CAD drawings are available on the web.

To speak with an applications engineer call 1-516-328-3970.

For additional information about the Heavy-Duty Slide 2, visit http://www.techno-isel.com/tic/Catdas/HeavyDutySlide2.htm.

Leave a Reply

You must be logged in to post a comment.