Fairfield, OH – A new high-speed reversing drive from Force Control Industries uses dual clutches to provide rapid reversing without undo strain on the motor or drive system. Unlike traditional reversing applications where the motor must accelerate in the forward direction, stop, then accelerate in the opposite direction and then stop again, the dual clutch Posidyne® eliminates stopping, starting, and accelerating the motor.

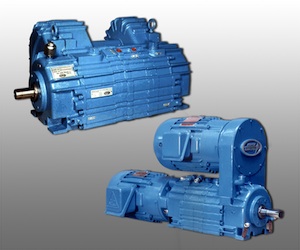

In the High Speed Reversing Drive (HSRvD) the input to the two clutches rotate in opposite directions. Force Control High Speed Reversing Drives are ideal for higher horsepower applications (up to 75 hp) that require reversing often, such as automotive production machines, machine tools, mineral processing, loading machines, and many more.

Several versions are available to suit many industrial applications. In the Type II HSRvD one motor rotating in the forward direction is connected through a primary clutch and a second motor running in a reverse direction is connected through the secondary clutch. By actuating the proper clutch and brake, the reversing is handled within the Posidyne® while the motor runs continuously.

In the Type I HSRvD there is only one input motor. The input to the two clutches rotates in opposite direction by means of a jack shaft through a reversing gear set.

The Force Control High Speed Reversing Drive uses less power than traditional start/stop systems, generating much less motor heat. Traditional systems reverse the drive motor each cycle, so the major inertia load is typically the motor rotor itself, degrading the motor’s service life. With Force Control, the motor runs continuously while the reversing is accomplished with the Posidyne® resulting in significantly longer service life for motors.

Oil Shear Technology is the reason that brakes by Force Control do not need constant maintenance, adjustment, disc replacement, and last up to 10 times longer than standard dry friction brakes. Oil Shear Technology is the function of a boundary layer of transmission fluid in shear between the friction disc and drive plate. As the parts come together the fluid under shear will transmit torque between the two parts as well as absorb heat. This eliminates direct contact of the friction discs and drive plates during high speed slip. Heat from the friction surface is dissipated as the fluid circulates to the housing.

For more information, visit www.forcecontrol.com.

Leave a Reply

You must be logged in to post a comment.