by Naoki Yamaguchi, Assistant Technical Manager, NB Corporation of America, Hanover Park, Ill.

With an understanding of how to manipulate six factors, you can increase a ball spline bushing’s load capacity.

Place a recirculating ball bushing on a shaft and what do you have; frictionless movement of the shaft. Create grooves along the axial length of the shaft that correspond to the radius of the bushing’s ball elements and you have frictionless linear movement coupled with two important characteristics – anti-rotation torque transfer and higher load capabilities. Now that’s a ball spline.

A ball spline combines a linear bushing (nut) that can handle greater moment loads and a shaft that can be rotated when needed. It is a good choice for applications involving high-speed motion and high-speed rotation.

Ball splines suite a number of automated operations: robotics, inspection, spinning, loading, coating, wire winding, grinding, indexing, die setting, transferring, conveying, molding, drafting, measuring, optical measuring, welding, riveting, printing, book-binding, packaging, filling, pressing, and more.

Then why is the selection of a ball spline difficult? One reason is the semantic differences in the literature. Demystify them, and it will be easier. To clarify, think of ball splines in terms of how their various configurations affect their function and then compare that function to application requirements.

Six load and accuracy factors

The ball spline bushing (generally referred to as a nut) has a load capacity (including moment load) that can be increased by manipulating any of six factors – four of which relate to the area of ball contact. These four are the number of grooves in the shaft, the shape of the grooves, the length of the nut and of its raceways, and tolerance. Five and six are shaft rigidity and mounting.

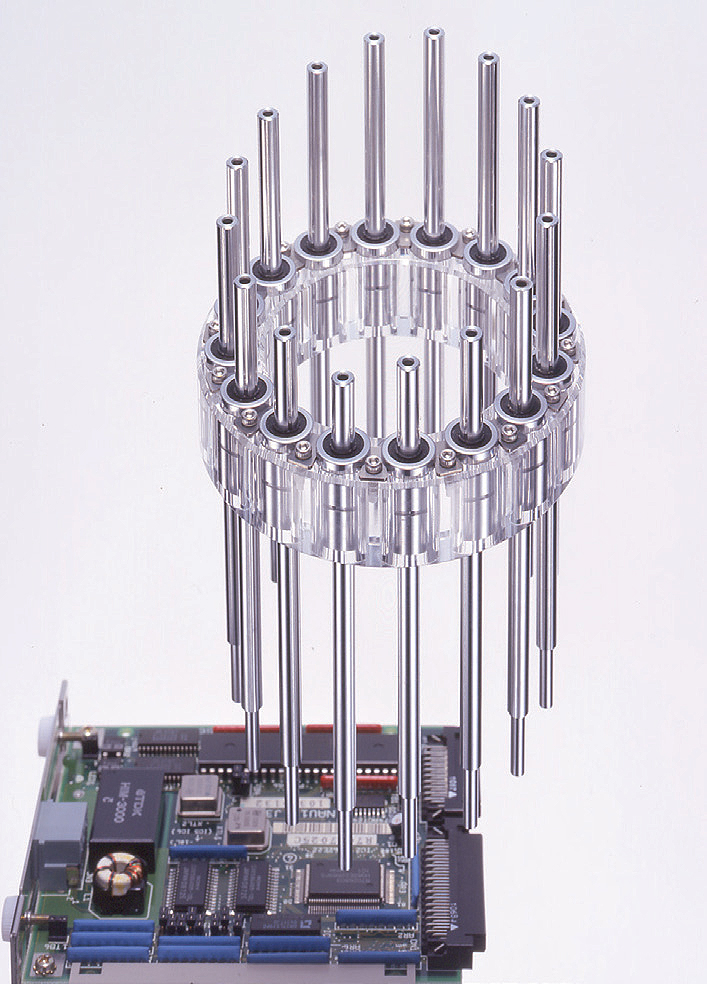

Sixteen ball splines with keyless mounts using special lock plates.

Number of grooves in the shaft. Compared to a slide bush shaft, a grooved spline shaft gives greater contact area so that load capacity and life are greater than a similar size slide bush and shaft combination. The basic dynamic load ratings of a ball spline are typically 5 to 12 times that of a slide bush of a similar size.

The number of grooves in a spline shaft range from two to six. However, in some instances the six groove system fills so much of the space on the shaft that there is no room next to the nut’s active ball paths for ball recirculation. Therefore, the nut has to protrude from the shaft for the balls to recirculate above and away from the shaft. Also, because the ball elements will fall out of the nut if the nut and shaft are separated, the six-groove-shaft ball-spline system must be handled with care.

In the most popular four-groove configuration, the nut can have side-by-side active and recirculating paths, which keeps the system compact. Plus, all ball tracks are in contact with raceways, whereas only half are in contact in any one direction on some six-groove shaft systems. So, if the load doesn’t require six raceways and four will do, you can save space.

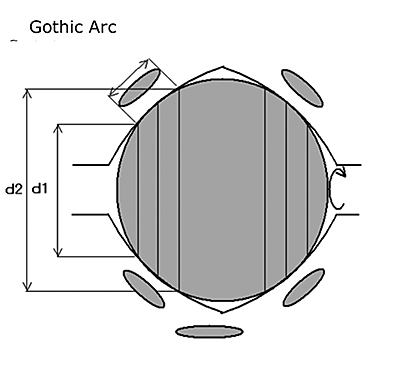

Shape of the grooves. The four-point contact design is, because of its shape, called a gothic arch. It eliminates any clearance that could lead to deflection and is, therefore, best suited for applications requiring maximum precision. Often found on larger spline sizes, this four-point contact increases the load capacity and rigidity so that this ball spline can handle a greater moment load.

Keyless cylinder nuts are suitable for small size compact applications.

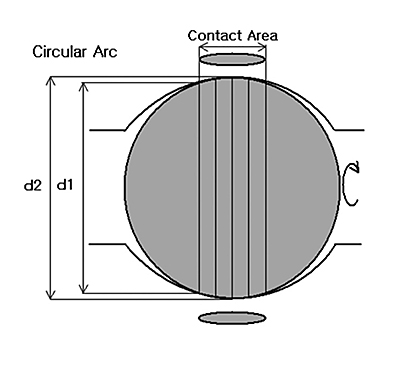

Of the groove designs on the market, the standard choice is between balls that make contact with the raceway grooves at two points or at four points. A slightly elliptical groove design allows the balls to make contact at two opposing points but allows a bit of clearance on the balls’ sides that are perpendicular to the contact points. A change of shaft rotation direction may cause backlash of this circular arc type nut. Because there are larger contact area differences on a gothic arc, the inner part of the balls must rotate faster than the outer, which creates slippage and results in greater friction. For this reason, circular arc grooves are used for smaller, more friction sensitive ball splines.

Another shaft configuration is available for very high loads. It uses semi-triangular protrusions along the spline shaft. Its main drawback is that it makes it more difficult for the user to machine the ends of the shaft and it is less stiff. This type of spline shaft is highly susceptible to vibration since straightness can be somewhat difficult to maintain. A round grooved spline shaft is stiffer because of the cross sectional area. It’s better with bending and twisting moments.

Length of the nut and its raceways. Since ball raceways are circuits, approximately half the balls in a raceway are always in the active, load-bearing portion of the raceway while the other half are in the recirculating path. Some raceways are designed to more efficiently take advantage of the nuts length and pack more balls into its active portion. The more active balls in the nut’s raceways, the more moment load the nut can support. To increase moment load capacity, multiple nuts can be used in tandem.

Nut tolerances. When raceways are precisely ground (not drawn) they better conform to the shape of the balls in the nut and grooved spline shaft. This results in opposing raceways having the same angles of contact, which eliminates backlash.

The clearance between the balls and the grooved spline shaft is controlled by grinding the nut and grooved spline shaft raceways accurately and also by installing the proper ball size grade – using the nut’s bearing outer cylinder wall to adjust to the different sizes.

Each spline nut should be individually preloaded at the factory with larger ball grades that reduce the clearance between spline shaft groove and nut groove. Where less vibration and less fluctuation of torque are present, standard pre-load is sufficient to ensure smooth linear movement. For a load subjected to minor twisting, alternating moment load and vibration, a light pre-load is preferable.

Preloading decreases the available radial play to ensure rigidity, which also increases precision. Preloading not only increases the contact area, increasing direct loading capabilities, it also restricts any radial movement, increasing the overhung moment capabilities for a sturdier structure that can handle demanding working environments.

Because there are larger contact area differences on a gothic arc, the inner part of the balls must rotate faster than the outer, which creates slippage and results

in greater friction. For this reason, circular arc grooves are used for smaller, more friction sensitive ball splines.

Shaft rigidity. Increasing spline shaft symmetry can increase maximum rotational speed and load capacities as well as reduce vibration.

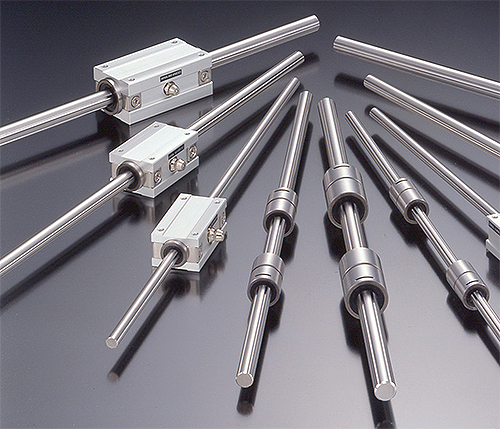

Spline shafts vary as to whether they are precision-ground, ground, or drawn steel bar. They also vary as to the grade of the base material. Manufacturers rank shafts by characteristics such as the tolerance of ground shafts, perpendicularity to the end face, concentricity of the part-mounting section in relation to the support section, as well as the material grade.

Controlling machining of all the shaft grooves so they are linear all the way through in high accuracies is very difficult. Non-ground (drawn) spline shafts are, naturally, of lower accuracy.

Generally, manufacturers present three accuracy ratings comparable to High (meaning their highest precision), Medium (meaning their standard grade – usually a stock item) and Low (often a non-ground shaft). However, one manufacturer’s top grade can be another’s standard grade. Comparing accuracy grades comes down to comparing measures of the above-mentioned ranking characteristics – shaft diameter tolerance, straightness, perpendicularity and concentricity.

If a lesser degree of accuracy is acceptable because the primary concern is torque transfer, linear transfer, rotational motion or length, then drawn, non-ground spline shafts may be the best choice. Some drawn shafts can use the same nuts as ground spline, but load capacity is reduced because the nut is traveling in a non-ground raceway groove. However, they are less expensive and can be as long as five meters, making them appropriate for material transfer and handling applications.

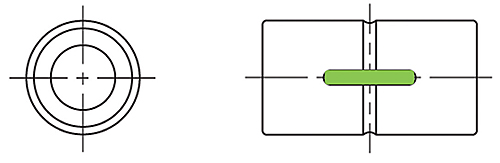

The standard mode of mounting a cylindrical nut is with a separate key for the nut’s keyway.

A matching keyway must be bored into the housing or block that will be mounted on the cylinder nut.

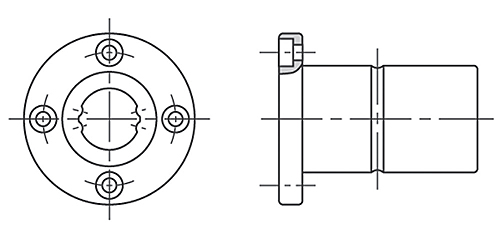

A flange nut is simple to install because it only requires a rough bore and mounting holes drilled and tapped to secure the flange to the housing.

Mounting systems. If the load is not mounted onto the nut securely, accuracy will be affected. There are three types of mounting systems.

The standard mode of mounting a cylindrical nut is with a key. For this system, the cylindrical nut will have a keyway and separate key. A matching keyway must be bored into the housing or block that will be mounted on the cylinder nut. It is critical that the bore precisely fit the key to prevent vibration.

The keyway is important because the nut must be fixed in a rotational direction so when the grooved spline shaft is turned, the nut isn’t turned within the housing. The housing has to turn with the nut. In addition to the key slot in the middle of the nut, this system also requires a snap ring, a push plate or another fixing method to prevent the nut from slipping out of the housing.

The second mounting system is the flange nut. A flange nut is much simpler to install because it only requires a rough bore and mounting holes drilled and tapped to secure the flange to the housing. Though, to fit the nut into the housing, a hole must be bored, this boring does not require the accuracy demanded by a keyed nut. With the flange type, because it is bolted on to the housing, there is no need for a keyway.

The third mounting system is the keyless cylinder nut. It is suitable for small size compact applications. It is similar to a flange type nut. Instead of a fixed flange on the nut, there is a squared attachment that slots into the nut to prevent rotation. The slot can be made with holes for screws so that the nut will be fixed similarly to the way that the flange is fixed to housing. But it is much more compact than the standard flange.

Discuss this on The Engineering Exchange:

NB Corporation of America

www.nbcorporation.com

::Design World::

Leave a Reply

You must be logged in to post a comment.