Updated May 2019. || Brakes and clutches are a mainstay in motion designs that need to stop, hold or index loads. Especially over the last five years, a technology trend toward application-specific designs has quickened as several industries are pushing the performance envelope of stock components.

First step:

Pick between clutches and brakes

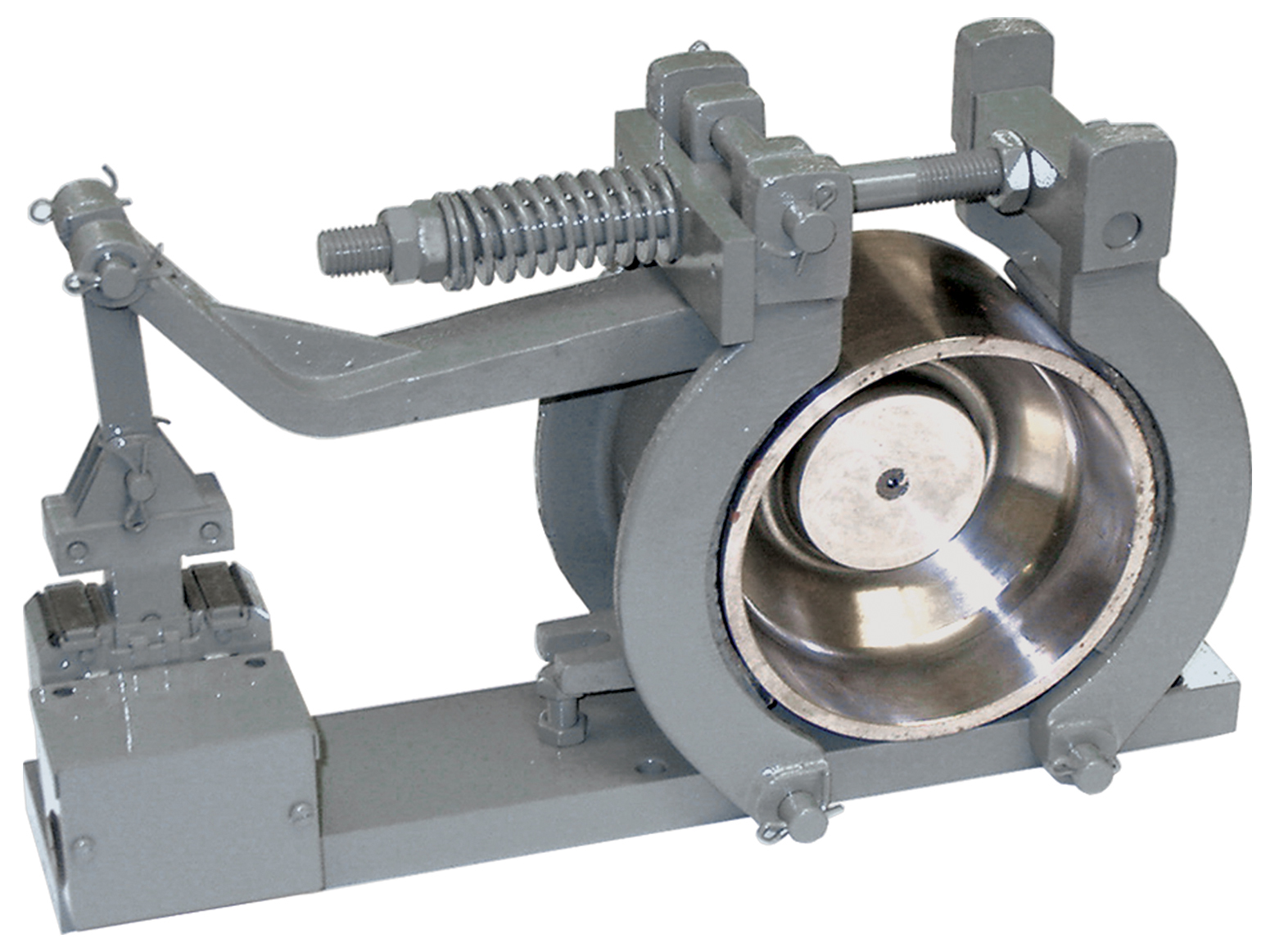

Brakes are used to stop a load (typically a rotating load) while clutches are used to transfer torque. Brake and clutch subtypes abound.

Brakes go in applications where accurate stopping of the load is needed and the motor will stop as well.

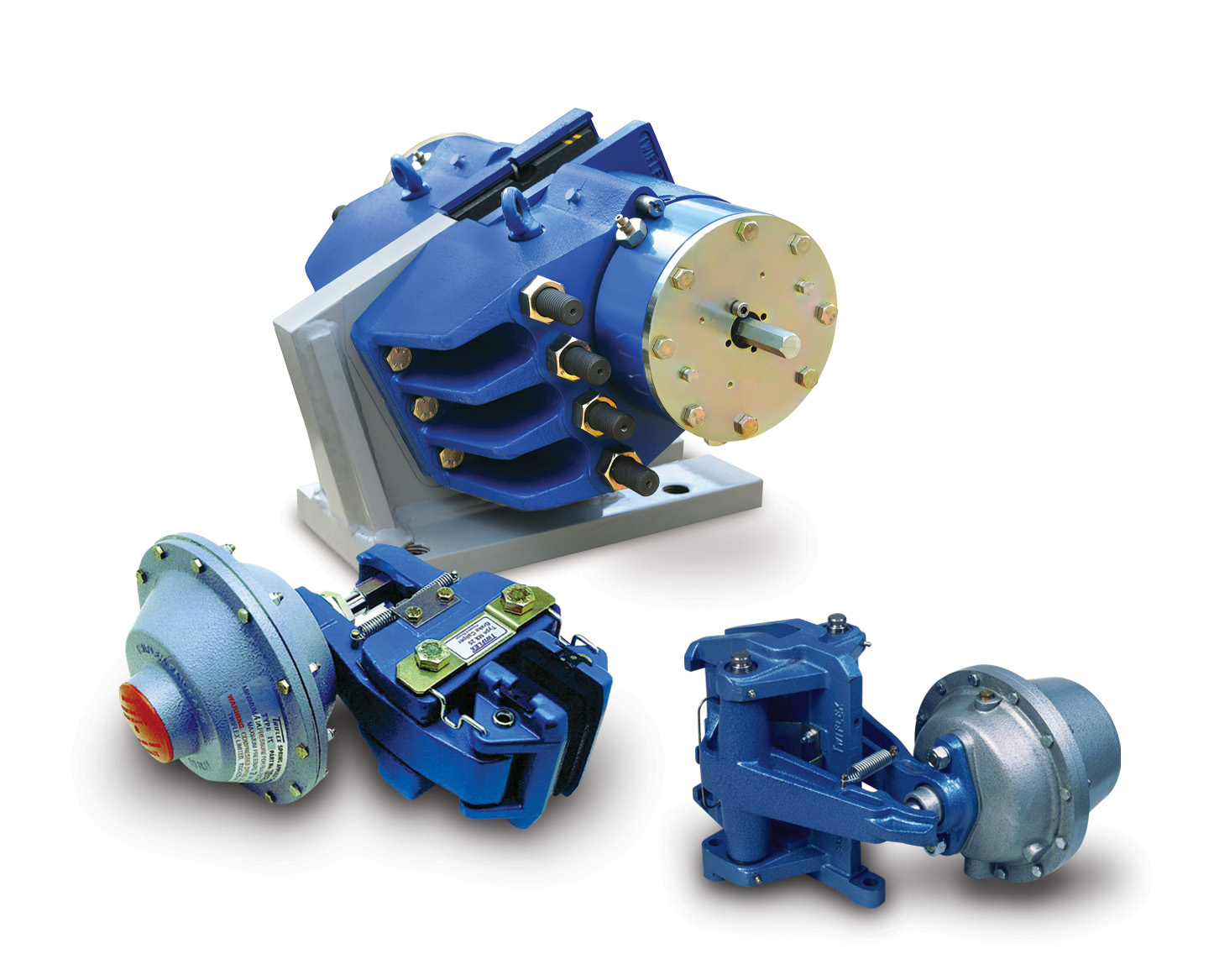

Clutches go in applications where the engineers must engage or disengage a load and motor while leaving the motor to run all the time. When a clutch is used, the load can coast to a stop.

Clutch and brake combinations go where load is started and stopped while the motor continues to rotate. Both clutches and clutch brakes can mount to a motor shaft or be base-mounted and have input through a belt drive, chain drive or coupling.

Second step:

Match to motor power

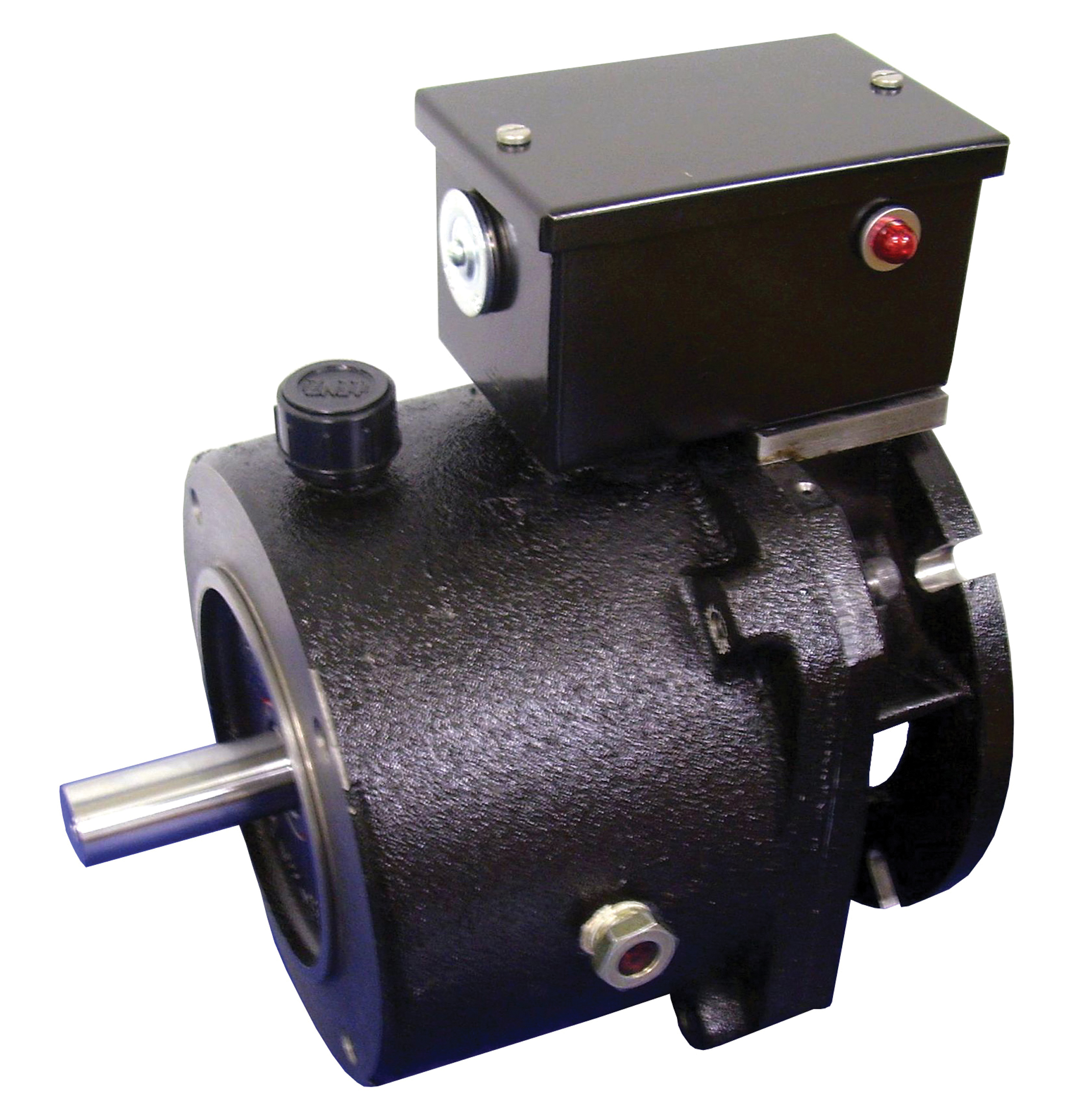

Motor horsepower plays a key role in determining which specific brake or clutch to select. In the case of base-mounted units, it may be necessary to define the rpm where the clutch or brake is to mount.

Manufacturers provide quick-selection charts that list unit sizes. With these, engineers can finding the intersection of motor horsepower and speed at the clutch shaft to identify size. Most such charts use the dynamic torque capacity for the product and the torque capacity for the motor plus an overload factor of some value.

Using this method presumes that you’ve selected a motor that’s sized appropriately to the application. In applications where cycle rates are considered aggressive for the inertia of the load, it’s a good idea to consult with the application support staff of the manufacturer regarding the clutch or brake heat dissipation capacity.

Third step:

Match to motor frame size

Next, determine the motor frame size. In some cases, a given motor horsepower may have more than one frame size choice. For instance, one-horsepower motors can be either a 56C frame or a 143TC frame-motors.

Because this impacts shaft size, it’s a critical piece of information to have.

As with the identification of horsepower and speed, manufacturers provide charts that list unit size and frame size. Because frame size determines unit shaft size, that factor is pre-determined.

Fourth step:

Pick mounting

The next choice is unit mounting. Both clutches and clutch brakes can mount to the motor shaft or be base-mounted and have input via a belt drive, chain drive, or coupling.

Fifth step:

Determine coil voltage

The last variable is coil voltage. The most common options are 6, 24 and 90-Vdc … with 90-V widely preferred in North American markets and 24 V more common in Europe. In both cases, clutch/brake manufacturers can provide power supplies to convert AC to DC if required.

Leave a Reply

You must be logged in to post a comment.