Updated July 2018 by Lisa Eitel || Several parameters dictate the most suitable helical compression-spring selection for a given application.

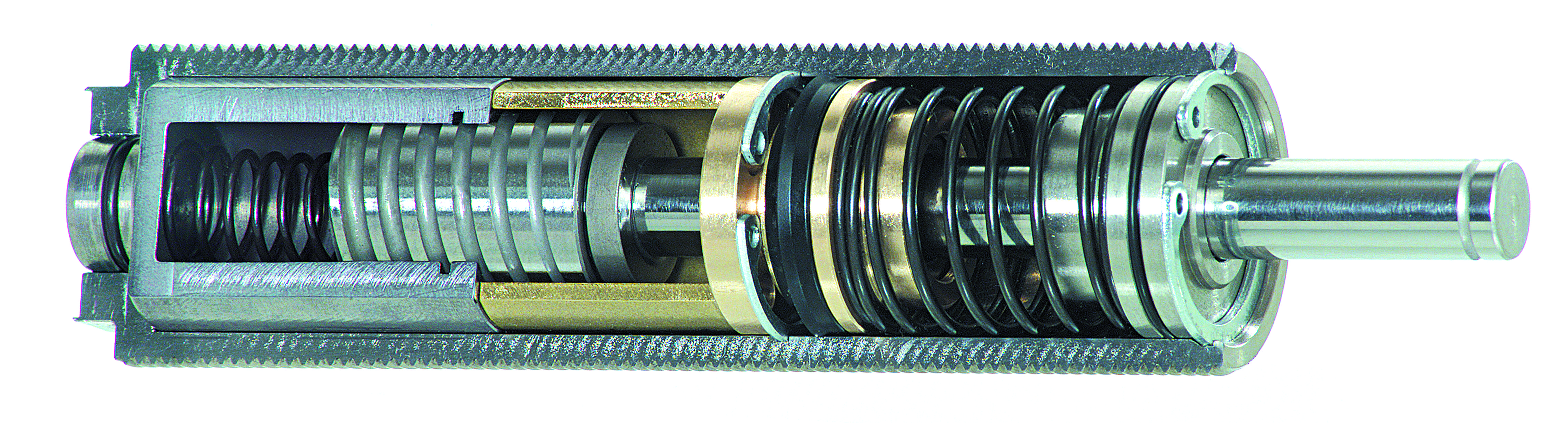

The OD of a spring expands under compression. Consider this if the spring goes into a tube or a bore during assembly. Also remember that the OD of a spring is subject to manufacturing tolerances, just as any mechanical part. If the tolerance range is positive, the spring’s dimensions may be slighter larger and can add to the overall assembly’s envelope size.

Most spring suppliers specify work-in-hole diameters for their springs to factor in manufacturing tolerances and the OD’s expected expansion. Look for this information to select from stock spring catalogs, or use this information to better communicate product needs when ordering custom-made springs.

Consider loading or travel requirements on the compression spring. The spring rate (also called the spring constant) is the relationship of the force to compress a spring by a unit of length, typically pounds per inch. So with a given load, the product designer can calculate expected spring travel. The further the spring travels, the more stress it endures. So at a critical point, stress can yield the wire material … causing a phenomenon called spring set. After spring set, the spring can’t expand back to its original unloaded length. Even so, in some assemblies, such springs can still function.

Stress formulas and online calculators predict spring set. Otherwise, a starting rule of thumb is to avoid solid height by at least 20% (so that there’s always 20% of the spring’s total travel left during the normal range of operation).

Compression spring-end types are standard or special. Standard ends are either plain open or closed. Either can be ground or not ground. The ends actually affect the spring rate. So, springs with dissimilar ends that are otherwise identical (with the same total coils, wire size, and OD) have different spring rates. Ground ends require more manufacturing effort. However, combined with closed ends, round ends improve the squareness of the loading force and reduce spring-buckling tendencies.

Some manufacturers include closed and ground ends in standard catalog stock design, while some don’t. Be sure to know the difference. Special end examples include reduced coil for screw mounting, offset legs to work as alignment pins, and enlarged coils to snap into ring grooves.

Spring materials abound and include everything from carbon steel to exotic alloys.

Music wire is a high-carbon spring steel and is the most widely used material.

Stainless steel 302 has less strength than music wire, but adds general corrosion resistance.

Nickel alloys are used in an array of trademarked springs. These excel in environments that subject the compression springs to extreme operating temperatures or corrosive elements — as well as applications that need non-magnetic motion components.

Springs made of copper alloys such as phosphor bronze and beryllium copper resist corrosion and provide electrical conductivity.

Leave a Reply

You must be logged in to post a comment.