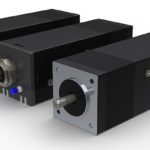

Applied Motion Products offers StepSERVO Closed Loop Integrated Motors for closed-loop servo control of position, velocity and torque resulting in higher acceleration rates and faster machine cycles in food & beverage applications. Combining a high-torque step motor with an on-board drive, encoder, controller and closed-loop servo software into a single package, the integrated motors save on space, wiring, and cost over conventional systems comprised of separate motor and drive components.

Using encoder feedback, closed-loop step motor systems automatically reduce current to the motor when torque is no longer demanded by the load to consume less power than a traditional step motor system. StepSERVO Integrated Motors also operate cooler and more quietly than open-loop step motors by drawing just enough current to control the load.

The ability to execute stored programs created with Applied Motion’s Q Programming language enables users to apply complicated logic and motion sequences to solve their motion control challenges. For example, in a product labeling application in a food and beverage plant, a product sensor can be tied to one of the motor’s digital inputs, triggering a WI (Wait Input) command when the product nears the labeling position. To prevent wrinkling or tearing, the label must be applied at the same speed the product is traveling on the conveyor. To accomplish this, the motor measures the conveyor speed from a master encoder whose A/B quadrature signals feed into the motor’s X1 and X2 digital inputs. The FE (Follow Encoder) command automatically ratios the label speed to the master encoder frequency while monitoring the label sensor to position the label at exactly the right location on the product. The powerful math capability built into the Q Programming language provides additional customization and control options.

Applied Motion offers its StepSERVO Integrated Motors in IP65 rated versions for wet and dusty environments. Units are available with industrial network communications including CANopen, EtherNet/IP, Modbus RTU and TCP, as well as support for third-party PLCs and HMIs.

For more information, visit www.applied-motion.com.

Leave a Reply

You must be logged in to post a comment.