Miki Pulley’s ALS couplings are general-purpose power transmission couplings designed to transmit torque by connecting two shafts while damping system vibrations and accommodating misalignment.

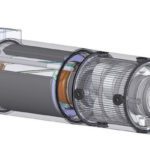

With a “Curved Jaw” design, ALS couplings feature a polyurethane elastomer element (called the spider) between two sintered aluminum hubs. The three-component assembly fits together with a jaw from each hub precisely fitted with lobes of the spider. In operation, the jaw coupling torque is transmitted through the elastomer lobes in compression.

The ALS elastomer spider elements are available in different hardness values. Users may choose the correct value for specific performance requirements. Each spider element features a slight curve allowing for pre-compression with no backlash.

The ALS coupling sintered aluminum hubs decrease moment of inertia when the system starts and stops. The spider element separates the aluminum hubs providing adequate torsional stiffness for accurate positional accuracy. It also allows for minimal angular and parallel misalignment while absorbing vibration and dissipating heat from adjacent sources in a system.

Another important feature of the Miki Pulley ALS coupling is its ease of installation design. Clamp style hubs slip easily onto two connecting shafts with the coupling locked into position with recessed tightening screws. They’re also available with pilot bore and keyed style hubs.

Handling system speeds from 4,500 to 34,000 rpm (depending on model), ALS couplings are RoHS compliant. They’re suitable for general-purpose motor connection including simple servo applications with high torque. They are available in eight models in bore sizes ranging from 3.0 mm to 60 mm. Transmittable torque for the eight sizes range from 2.0 Nm to 1,050 Nm.

In addition to the ALS coupling line, Miki Pulley designs and manufactures a complete line of motion control components. These include flexible shaft couplings, shaft hub locking devices, clutches, brakes and speed control devices.

For more information visit www.mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.