Keep these five key factors in mind when selecting mechanical components for harsh environments.

Chad Carlberg

Product Line Manager for Industrial Actuators

Thomson Linear

As electromechanical actuators and other mechanical motion components expand in capability for heavy duty applications, so does their capability to resist harsh conditions. Extreme temperatures, high particulate levels, chemical exposure, high-pressure washdowns, vibration and shock, radiation, and electromagnetic interference are among the threats to reliable motion control. System designers can mitigate these threats when selecting motion control components for such applications through careful evaluation of five design elements that contribute to robust operation: material selection, coatings, sealing strategy, vibration/shock resistance and maintainability.

Factor one: Material selection

Material selection is the first line of defense against challenging environmental conditions. Advances in material science are leading to the creation of new alloys and hybrid materials that can withstand temperature extremes, exposure to chemicals or abrasive materials, frequent washdown, and other environmental forces. Stainless steel, hard-anodized aluminum and resistant polymers are among the most common materials used to ruggedize motion control components.

Poor material selection can result in premature failures, expensive in-field service and repair, and lost productivity. Maximum protection comes when all motion control components – from the actuator housing to the smallest bearing – are selected with worst case operating scenarios in mind.

Factor two: Coatings

Motion control components used in extremely corrosive environments, such as those characterized by exposure to hydrocarbons, urea and fertilizers, should also be coated with high-performance materials. This improves operation and reduces downtime, especially in environments where corrosive chemicals, salt spray or submersion will require additional protection. The right coating and material combination can significantly extend component life.

Testing chemical resistance

The most widely applied standard for chemical resistance is ISO 15003, which provides design requirements and guidance for the manufacturers of electrical and electronic equipment used in mobile agricultural machinery, forestry machinery, landscaping and gardening machinery. It provides test protocols for specific environmental conditions and defines severity levels for extreme conditions that might occur during typical operation. Testing for chemical resistance, for example, requires the ability to withstand three days of operation amidst the following chemical concentrations:

- Diesel Fuel – 100%

- Hydraulic Oil – 100%

- Brake Oil – 100%

- Ethylene Glycol – 50% aqueous solution

- Urea Nitrogen – saturated solution

- NPK Fertilizer*9 (7.5% each N, P, K) – saturated solution

Other standards applied to corrosion resistance, particularly Diesel Exhaust Fluid (DEF), are DIN 70070-05, AUS 32 and ISO 22241-1.

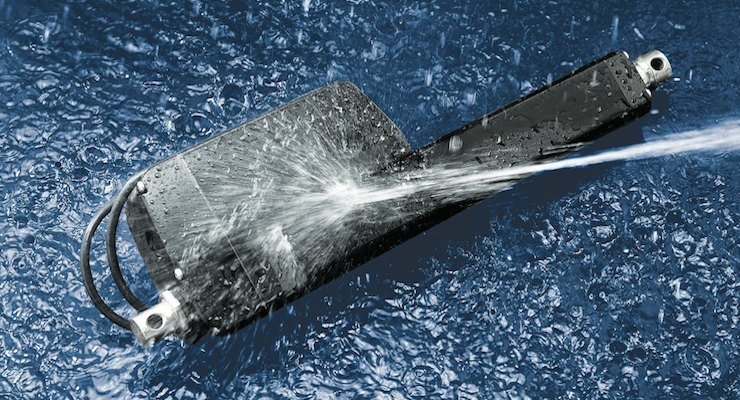

Factor three: Sealing strategies

After materials and coatings, the next line of defense in harsh environments is the sealing strategy. Unless a component is adequately sealed, chemicals and particulates can make their way to internal component mechanisms, causing damage, buildup and clogging, and creating fertile ground for bacterial and other microbial growth. Using inadequately sealed motion control components in harsh environments will require additional cost of enclosures and maintenance, and potentially more frequent maintenance.

Every component should be sealed, including motor mounts. Wipers, seals and gaskets are integral to success. The wiper brushes off contaminants from the extension tube during operation and prevents water intrusion. The seals back up the wipers to complete the protection. Lastly, gaskets provide sealing between housings, cover tubes, motors and rear mounting components.

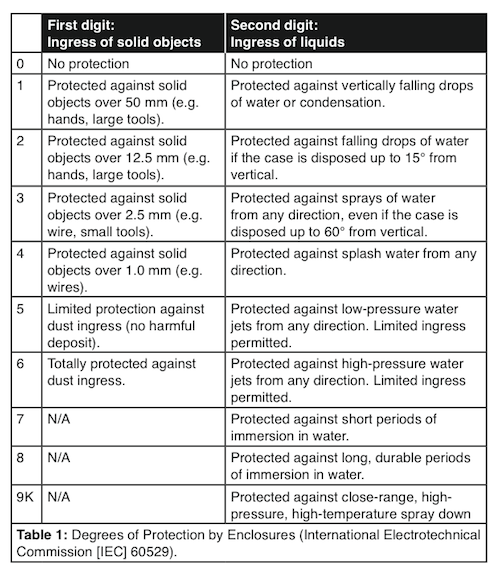

One of the best indicators of a system’s sealing effectiveness is the International Protection Marking, or IP Code. Its ingress protection (IP) rating is the global standard for measuring protection from the ingress of solid objects and liquids. The IP rating specifies the degree of environmental protection an enclosure provides against foreign materials that could impact operation.

The IP rating is composed of two numbers (see Table 1). The first number represents resistance to solids and the second to liquids. An IP rating of 00, for example, means there is no protection from solids or liquids. An IP rating of 11 means protection from ingress by objects larger than 50 mm and from rain or condensation. An IP rating of 66 means protection from penetration by particulates the size of dust and from high-pressure water jets from any direction. This rating is also considered the minimum for use in harsh environments today.

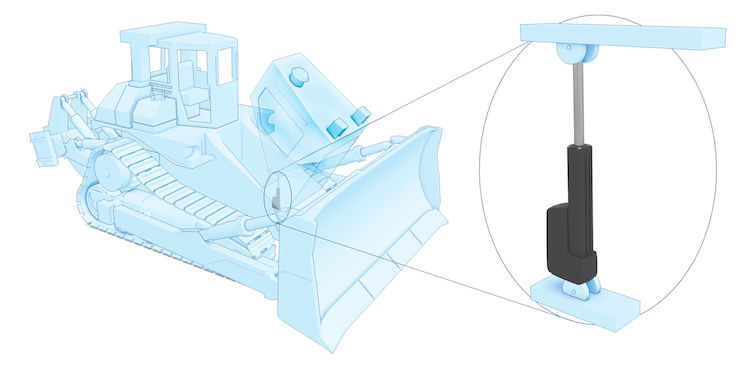

Factor four: Vibration and shock resistance

Materials, coatings and sealing can all be compromised by shock and vibration. Components must be tough enough to withstand the extremes of machines operating in harsh conditions. Often this translates into heavy loads or intense vibration or forces acting on the components – sometimes in near constant operation. The constant torque and movement can weaken a component over time and cause failure. By incorporating design features that account for high vibration or shock load, manufacturers eliminate the need for product accommodations.

For example, planetary gear designs provide more shock resistance than parallel gearing, and stiffness can be improved further by cutting one of the internal gears directly into the output housing. Leveraging a single-piece housing and ring gear, in this way, eliminates the chance of the gear slipping inside the housing, offering higher peak torque. Avoiding bushings with rolling elements can also help systems handle the constant stress environments as can depth/through case hardening of shafting. Proper mating of all components is also critical to shock protection.

Testing shock resistance

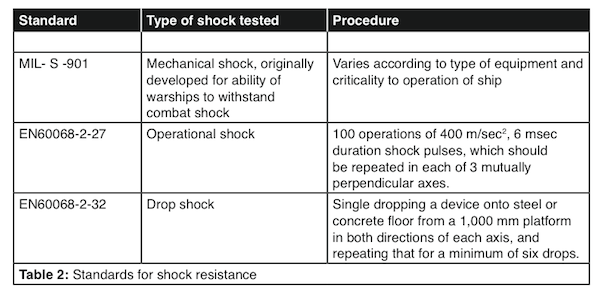

Compliance with industry standards is one of the best ways to ensure the right level of shock protection needed. Table 2 compares the three most common standards applied to motion control equipment: MIL- S -901, EN60068-2-27 and EN60068-2-32.

Testing vibration resistance

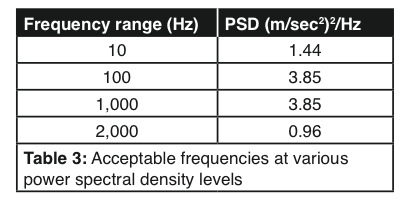

To ensure that common vibration profiles can be completed without damage to the product, test protocols, usually OEM specific, are run on multiple components and planes, including protocols for testing housings, structural bolts and any included printed circuit assemblies or sensors. Testing is conducted with the unit not powered or operating and mounted on a vibration machine guided by the power spectral density (PSD) levels shown in Table 3. The device being tested should extend half of design maximum and be tested in three orthogonal axes for 24 hours each.

Factor five: Maintainability

Harsh environments present risks to human safety from extreme temperatures, toxic/harsh chemicals or inhalation hazards – even radiation. Besides lost productivity and downtime, maintenance or replacement presents risk of injury or illness – especially if frequently done. Components that offer little to no maintenance improve employee safety and minimize potential for workplace accidents, while reducing costs.

Lubrication issues are one of the main maintenance drivers for linear motion components. Smooth, reliable motion is a hallmark of a well-designed system and is ensured by maintaining the proper level of lubrication for moving components. Products that use oil for lubrication require routine maintenance and are predisposed to leaks. Components that pre-lubricate with grease or self-lubricate can greatly reduce or eliminate ongoing maintenance demands.

The right stuff

A few examples from Thomson illustrate how motion components can be designed for operation in harsh environments. For instance, Thomson’s Max Jac heavy duty electric linear actuators are made of stainless steel, hard anodized aluminum or a highly resistant polymer. The seals are made of materials that withstand both organic and nonorganic chemicals and abrasive materials. They’re also designed to operate in a wide temperature range from -40 to + 85°C. The actuators are also rated for IP66/IP69K and have been tested for 500 hours of salt spray, withstand dirt, dust and water, and resist aggressive substances such as fertilizers, acid, oil, grease and cleaning agents.

Another example is the Electrak HD, which also uses stainless steel, e-coated zinc, and anodized aluminum materials to provide protection in heavy duty environments. It also features advanced sealing features with the added benefit of IP66 dynamic protection to keep the internal components free of ingress – even while the actuator is operating. The internal components themselves are protected from drops, shocks, and interference from other electrical sources to ensure proper operation, regardless of external application demands.

As long as harsh and hazardous environments require extended presence by humans, many opportunities to improve productivity will remain untapped. Motion control technology can reduce the need for human exposure, while at the same time enabling performance of operations beyond human capability.

But mechanical components require protection too, and careful consideration of materials, coatings, sealing strategies, vibration and shock resistance, and maintainability can help system designers ensure they will get maximum performance and life out of the systems they intend to deploy in challenging environments.

Thomson Linear

www.thomsonlinear.com

Leave a Reply

You must be logged in to post a comment.