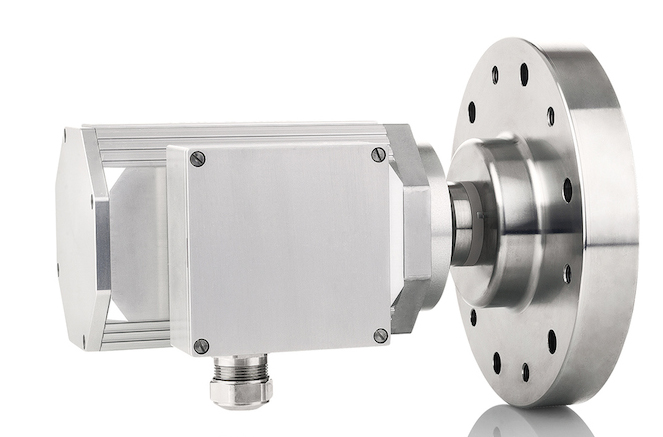

The Leine & Linde 1000 series rotary encoder with speed monitoring capabilities is used in applications where secure speed feedback is critical in order to protect motors, machinery or operators from risk of failure. This is especially useful on heavy moving machinery such as hoists, lifts, cranes and mining equipment, to name a few.

Leine & Linde’s overspeed electronics on the 1000 series consist of a speed detection system that senses rotational speed and direction. These electronics control three different relay switches which can be programmed for identification of critical speeds or errors in direction. A fourth relay can be set to detect overspeed conditions, or be set to detect any functional error in the unit itself.

As critical speeds can vary for different applications, the ability to program application specific set-points offers considerable flexibility. With this capability, a standard 1000 series encoder with overspeed electronics can be supplied and programmed for each installation. Speed limits can be set for direction, over and under speed from 0 to 6,000 rpm. PC-based software is provided to configure the encoder using a standard USB port.

The Leine & Linde 1000 is designed to meet requirements in real-world heavy duty applications. With sturdy bearings and enclosure, the 1000 series encoders achieve extraordinary durability towards mechanical stress. The encoder is rated at 200g shock, 30g vibration, and its IP67 enclosure can also withstand wet or dusty environments with high temperatures.

For more information, visit www.leinelinde.com.

Leave a Reply

You must be logged in to post a comment.