Aston, PA – The UH5 software program from Uhing Company enables rapid analysis of linear motion application requirements to assure correct size selection of Uhing rolling ring linear drives.

OEM designers and production personnel can submit linear motion application data by telephone or using forms on the Amacoil web site. Based on application criteria such as travel distance, weight of payload to be moved and desired ramp up time, Amacoil tech support specialists use the Uhing UH5 software program to quickly calculate technical and performance data such as required side thrust and linear travel speed.

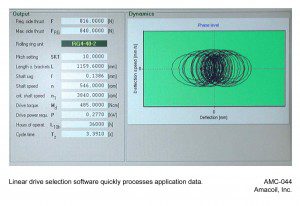

The software saves time and eliminates trial and error in selecting linear drive size. Complex drive selection criteria are calculated in seconds including shaft rotational speed, drive torque, power requirements and shaft sag. Additional output data includes Fourier transformation analysis (showing drive displacement versus distance traveled at a constant speed) and dynamic simulation charts for visualizing shaft deflection off the centerline in relation to shaft rotation speed.

As the exclusive North American distributor for Uhing, Amacoil provides sales, technical support, service/repairs and parts.

For more information please contact Amacoil at 1-800-252-2645, Fax: 610-485-2357, or email at amacoil@amacoil.com

Leave a Reply

You must be logged in to post a comment.