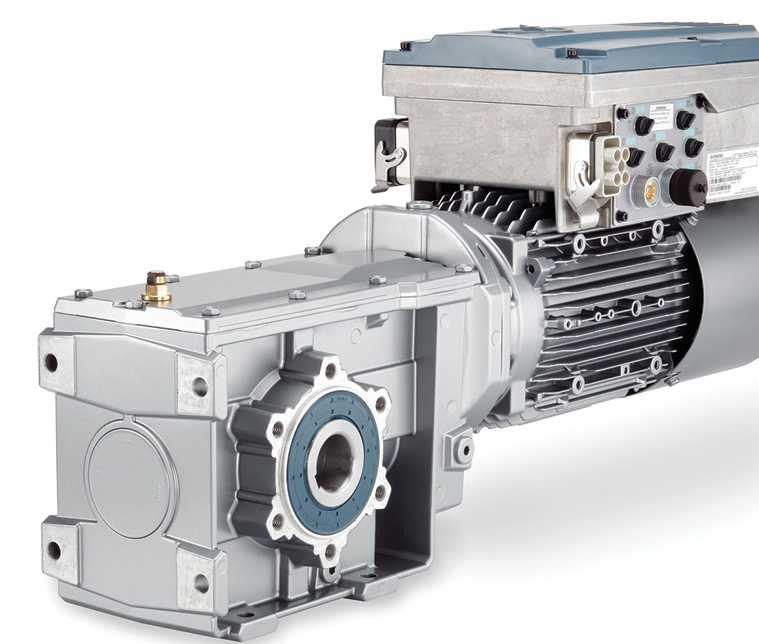

Applications that require a lot of force to move heavy loads are the most common for gearmotors. Most industrial gearmotors incorporate fixed-speed ac motors. However, some gearmotors use dc motors, which are common in automotive applications, among others.

It’s possible to combine many different motors and gearsets. However, not just any one will work for every application because certain combinations are more efficient and cost-effective than others. This is why knowing the application and getting an accurate estimation of its required torque and operating speed is the foundation for successfully integrating a gearmotor into a system.

Gearmotors typically outperform other motor-gear combinations. More importantly, gearmotors simplify design implementation because they save engineers from having to integrate motors with gears, which in turn reduces engineering costs. If the application requirements are known, engineers can order the right gearmotor directly from a supplier.

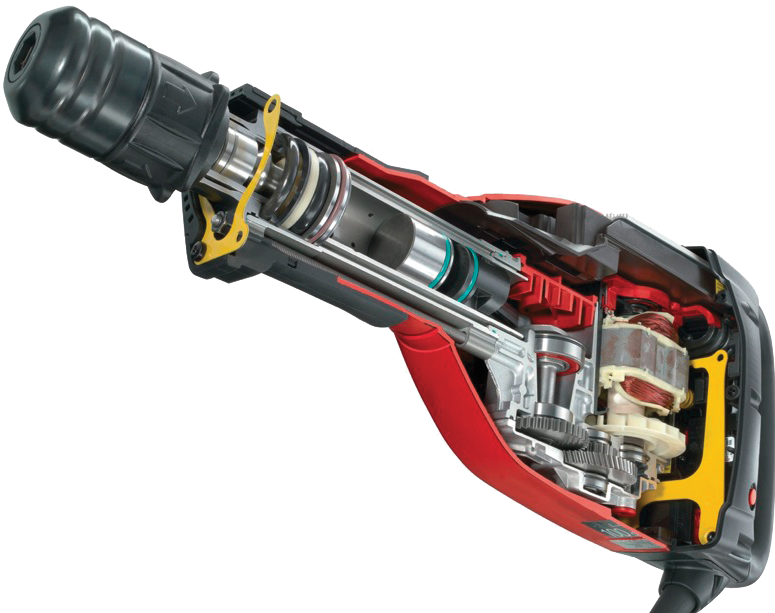

If a gearmotor is sized properly, having the right combination of motor and gearing can prolong design life and boost overall design efficiency. Gearmotors can also eliminate the need for couplings and potential alignment problems that come with those components. Such problems are common when a design includes the connection of a separate motor and gear reducer, which in turn increases the potential for misalignment and bearing failure.

As applications for gearmotors expand, manufacturers are seeing a change in expectations from end users. For instance, end users have an increased expectation for more integrated designs. Meanwhile, other companies have found that the design requests they’re receiving are becoming more complex, requiring more customization and creative thinking.

Leave a Reply

You must be logged in to post a comment.