The new maxon DCX program offers high power and can be configured and ordered completely online.

On maxon’s microsite, you can find brushed DC motors, planetary gearheads and sensors and now in addition maxon has rolled out all new configuration software: DCX motors, GPX gearheads and ENX encoders can be configured and ordered online.

“We have invested all our know-how in the maxon DCX program. By optimizing the subassemblies and using high-performance magnets, we succeeded in making the new drives smaller and more powerful. Simultaneously, we have developed new production technologies and significantly improved existing processes,” says Eugen Elmiger, CEO of maxon motor. For example, the DCX 35L, with a diameter of 35 mm, has a speed/torque gradient (4 rpm/mNm) close to that of the existing RE 40 DC motor (40 mm diameter, 3.5 rpm/mNm). Furthermore, all DCX drives can be configured on the Internet and has short delivery times.

For individual requirements: Configure and order online.

The DCX 22 S has stainless steel or graphite brushes, can be equipped with standard preloaded ball bearings or sintered bearings and covers a large voltage range with six different ironless windings, System maxon®. With the new housing, almost all mechanical configurations are possible. For example, the flange can be equipped with different fastening screw threads and mounting centering options. For use in small spaces, the DCX motor is also available in a very short configuration without flange. The length and diameter of the drive shaft can be selected, with or without face. The DCX motors can also be ordered with or without cables. Cables are available in various lengths and with plugs.

For the entire system: Configure GPX gearhead and ENX encoder with the drive.

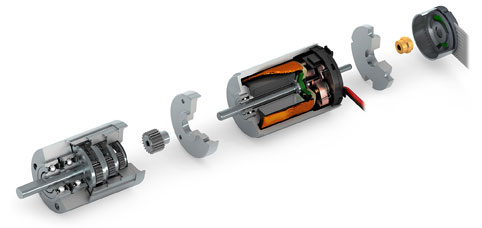

Furthermore, maxon motor has developed new gearheads and encoders for the DCX motors. The GPX gearhead consists of individually configurable gear stages and is now even more silent and robust. With a robust laser weld, the gearhead interface is joined seamlessly to the DCX motor. The GPX gearheads also come with a configurable flange. The shaft is available in different lengths, with or without a face, and even with cross holes or a key.

Matching maxon ENX encoders feature a robust design and high signal quality. The ENX QUAD encoder is a single-pulse, 2-channel encoder. It is used for speed and direction detection. With ESD protection network, reverse polarity protection, cable strain relief and the general robust design, it is an economic choice for simple closed-loop tasks. The ENX EASY is a 3-channel encoder with line driver in acc. with RS422. A resolution of up to 1024 pulses can be programmed ex works. Thanks to the cable strain relief, it is an excellent choice for high-precision position and speed control. The cables of the ENX encoder are configurable in seven lengths, from 50 mm to max. 1000 mm.

Combined, maxon DCX, GPX and ENX form a high-precision, robust drive system for a wide range of applications: The new maxon products are of interest in particular for medical technology, robotics, or in the aerospace industry. All DCX products can be operated with positioning controllers and servo amplifiers of maxon motor.

“These new configurable drives provide our customers with direct access to the maxon development. With just a few clicks of the mouse, it is possible to configure own powerful DCX drives with reliable and fast delivery date confirmation. Detailed product data can be viewed online immediately, and 3D data for the configuration is available for downloading,” says Eugen Elmiger.

For detailed product information and direct access to the configurable drives, visit dcx.maxonmotor.com.

Leave a Reply

You must be logged in to post a comment.