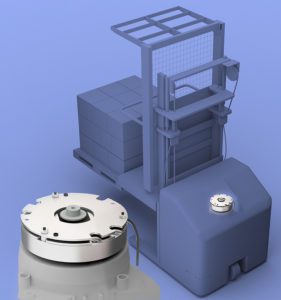

“Lock-In-Place” Brakes from Miki-Pulley provide long-term positioning for direction control wheels on picking forklifts and similar applications.

Designed for both braking and holding, these Power-Off engaged BXH model brakes from Miki-Pulley are opened using an electromagnetic field, and hold in a default closed position with compression springs. They have double the torque of similar brakes for dynamic braking purposes. They provide reliable braking when the power is disengaged and excellent performance in long-term holding applications.

These brakes provide power-off, fail-safe braking in the most demanding applications. The primary moving part in this robust brake design is the armature plate. To open the brake and allow free rotation, current is applied to the stator coil producing an electromagnetic field, attracting the armature plate to the stator and away from the rotor disc. When no current is applied (power-off), recessed compression springs push the armature plate back into the rotor disc to halt and hold rotation. This feature provides fail-safe braking and allows the brake to maintain position over long periods of time without power consumption.

Additional features include: quiet operation, high holding torque, lightweight, space saving design configuration, long service life, stable and reliable braking power. Easily installed, these Miki Pulley Power-Off Engaged Brakes require no maintenance.

Miki Pulley BXH Power-Off Engaged Brake specification range:

• Brake torque: 2.950 ft/lb to 32.452 ft/lb (4Nm-44Nm)

• Brake outer diameter: 3.268 to 76.221-in. (83mm to 158mm)

• Ambient Temperature: 14 F ~ 104° F; (-10 ℃ ~ 40 ℃)

Additional applications include robotic systems, printing presses, food and paper processing systems, packaging equipment, textile manufacturing systems and many servo & stepper motor driven systems plus many more.

Miki-Pulley

www.mikipulley-us.com

Leave a Reply

You must be logged in to post a comment.