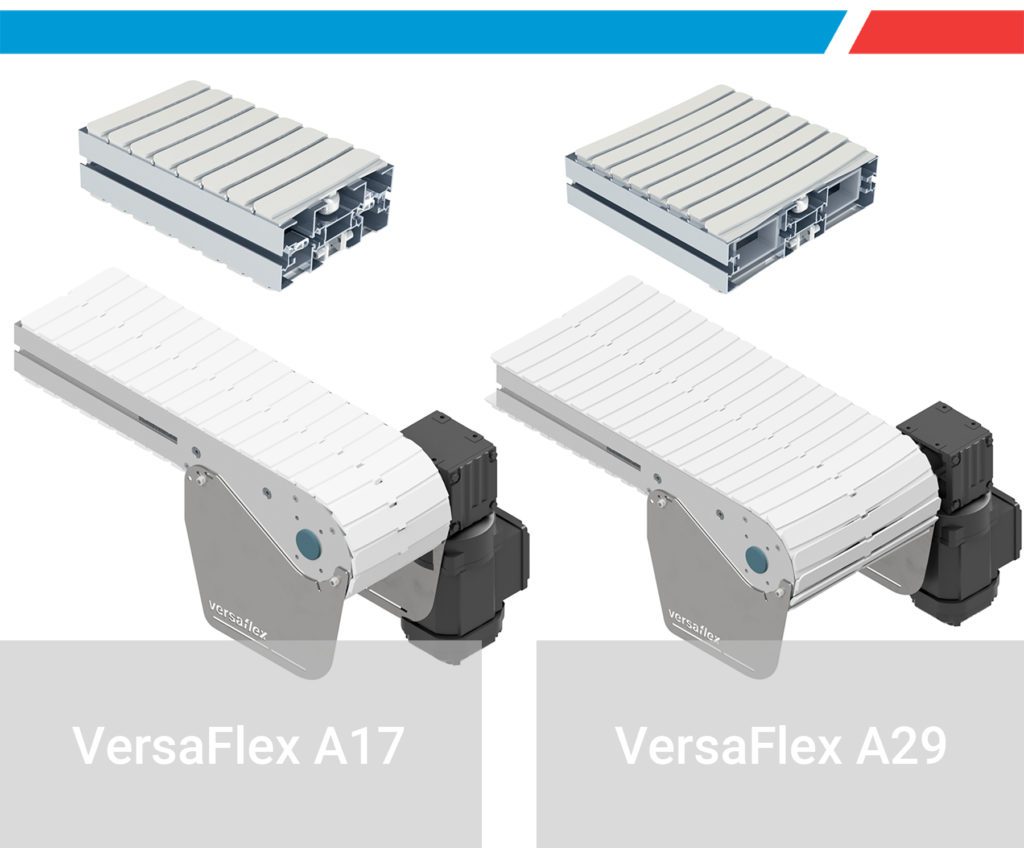

Leading conveyor system designer and manufacturer, mk North America has introduced two new conveyor models to its VersaFlex flat top chain conveyor system. Both the A17 and A29 add length and width capabilities – so larger products or those requiring extra support, can easily make their way through the conveyor line. All while maintaining the efficient and affordable footprint the product line is best known for.

mk North America’s VersaFlex flat top chain conveyor system is a highly modular, flexible system and is ideal for complex layouts and features simple and fast configuration and commissioning possibilities.

The conveyor system features different chain widths and track designs and can transport primary and secondary packaged products as well as workpieces for assembly lines. One the greatest competitive advantages of VersaFlex is that it can adapt to elevation changes, curves and straight sections – all while being driven by a single motor.

“We are very excited to continue to add to our already versatile VersaFlex product line; with the addition of the A17 and A29 VersaFlex systems we now build on our ability to handle larger size products while still having this same flexibility for a range of applications. These larger frame sizes will now allow us to provide robust solutions while still maintaining the same capacity and efficient footprint ability as our other VersaFlex systems,” said Michael Zampano, Mechanical Design Engineer, VersaFlex.

The VersaFlex A17 has a chain width of 175 mm and a system width of 182 mm. It can convey a product width from 70-400 mm and operate at a max speed of 50 m/min.

The VersaFlex A29 has a chain width of 295 mm and a system width of 300 mm. It can convey a product width from 70-400 mm and operate at a max speed of 50 m/min.

“With the ever-evolving field of automation and solution-based needs, we are thrilled to announce the addition of our A17 and A29 VersaFlex systems. This will allow our customers to facilitate large-scale product applications without compromising the overarching advantage of the VersaFlex platform: extreme versatility and functionality at an affordable price,” commented Scott Blais, Jr – Inside Sales Manager, mk North America.

For more information, visit mknorthamerica.com.

Leave a Reply

You must be logged in to post a comment.