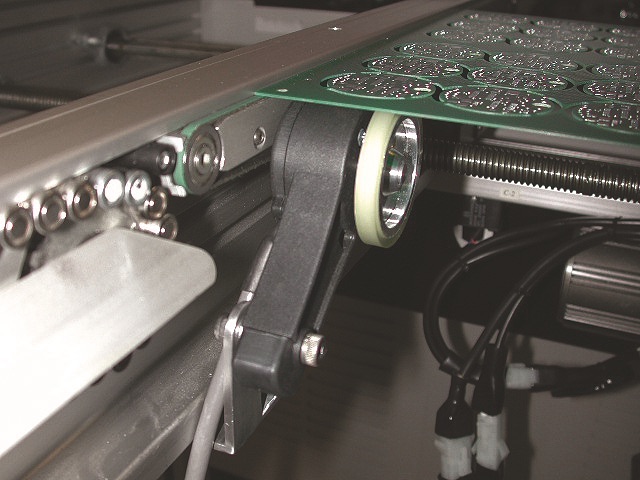

Encoder manufacturers are making sure that their offerings keep pace with broader technological changes and the demands of the market. For example, more powerful motion controllers and drives have spurred a rise in more sophisticated automation systems across a range of industries and applications. Robotics in particular is one area that continues to see growth, with a corresponding increase in demand for all sorts of motion-related components, including encoders.

When asked about the trends they’re seeing in encoders both from a technological point of view as well as broader market and industry trends, here’s what some leading encoder manufacturers told us:

Are you seeing any activity with increasing encoder capabilities that are spurring demand for higher-performance networking and connectivity options?

Kevin Taylor, Engineering Manager, Design & Development Group, Encoder Products Company

Yes. Absolute feedback, increasing resolution, lower latency, and reducing wires and associated costs are all driving advancements in communication protocols and signaling technology. For example, BiSS C and BiSS Line have implemented these performance improvements to help close the feedback loop in motor control applications. Even with these advancements, traditional incremental encoders are still a preferred solution for many applications because of their real time capability, wide acceptance, ease of implementation, and low cost.

Jonathan Dougherty, Business Development Manager – Automation, HEIDENHAIN

We are seeing more demand for the ability to network other sensor information in to the encoder feedback communication. This allows for a more streamlined channel for many base sensors in a given machine and limits the number of wires and connections needed back to a control.

Is there anything noteworthy in motion control networks that you are seeing, particularly given the demand for more data and IoT and Industry 4.0, etc.? Do you find customers asking for any particular network? Or is it still a kind of Wild West of networking out there with many different networks optimized for specific applications and uses?

Kevin Taylor, Encoder Products Company

In many cases the network or serial bus is driven more by the industry segment and the features they need. For example, BiSS C and BiSS Line are well suited for servo motor feedback loops. EtherCat is a common choice for networking between motor controllers. The AGV market is more inclined to use CANopen. For larger scale installations, the choice is influenced by the selection of the overall control system.

Jonathan Dougherty, HEIDENHAIN

The types of interfaces out there can be quite extensive and each version does have its own advantages and disadvantages. A lot of the reasoning for choosing one interface or another is influenced by the application specifications and the specific tasks you want the interface to perform. There is certainly a plethora to choose from at this time but I believe that as these industries mature with this technology, we will start to see a concentration to a core set.

What role does data play in your product designs, specifically with regard to big data, IoT, Industry 4.0 and beyond?

Jonathan Dougherty, HEIDENHAIN

We are cognizant of the fact that current and future applications will require the ability to handle large amounts of data and communicate this back to the controllers. In preparation for this, we’ve engineered and released unique solutions to better prepare ourselves and our customers for this reality. One example is our new encoder interface EnDat 3. This next generation of EnDat is specifically designed to accommodate significantly more external sensor information within the pre-established encoder communication stream. With this you can connect up to 15 additional sensors to monitor environmental conditions like temperature, vibration, humidity, and others. This lets users have access to more detailed information about the health of their machine and monitor critical aspects in real time.

Another offering of this type is available in our Leine Linde brand encoders which can come with our Advanced Diagnostic System called ADS Uptime. This system monitors the key functions and conditions which affect the health of the encoder and provide this information through an existing hardline connection or over Bluetooth directly to a phone or tablet. This Bluetooth feature allows maintenance personnel to have easy access to view the condition of the encoder and even provides an easy-to-read overview of encoder health like a decreasing battery charge as you see on your phone. Once the encoder health reaches a certain threshold (say 20%), you’re provided a warning stating it may be time to do maintenance for this part allowing users to move towards a more predictive maintenance cycle.

Kevin Taylor, Encoder Products Company

So far, it’s small at the encoder level but gradually increasing. Delivering these features is challenging since many customers don’t want to absorb the additional cost. The demand is also limited by the rate at which companies can invest in updating factories with new technology.

Has your company seen increased activity or demand from customers in any specific industries or application areas?

Kevin Taylor, Encoder Products Company

Encoder demand is increasing across a broad range of industries and market segments. The common factor is automation – any application where there are opportunities to reduce manual labor, improve quality, minimize dangerous or repetitive work, increase throughput, and reduce overall costs.

Jonathan Dougherty, HEIDENHAIN

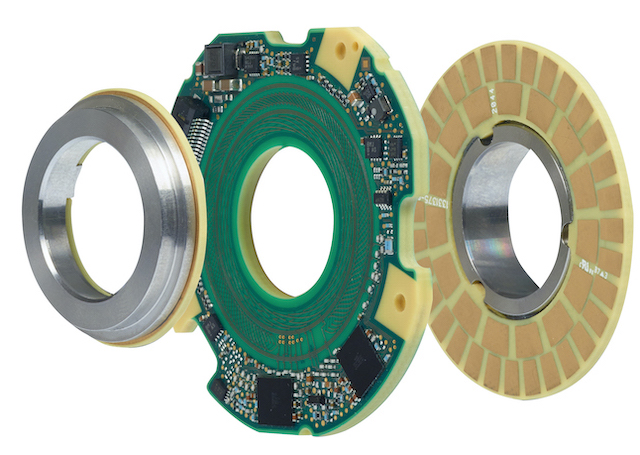

We have certainly seen an increase in the robotics and medical spaces over the last couple of years. Within the robotics market, you are starting to see more companies releasing collaborative robot options, or Cobots as they’re called, into the market. These are robots specifically designed to operate alongside of a person fulfilling a task. This provides a level of automation but also keeps a human worker involved for tasks that are complex enough to require in-person collaboration. Beyond that we are also seeing safer industrial robots that operate without the restriction of a cage. This allows for more floor space in a factory but does require a high level of safety to make sure the risk of a failure is as reduced as possible. In both these situations making sure you have the right position and speed feedback is important as this directly contributes to the safety rating of the robot. HEIDENHAIN offers pre-certified Functional Safety encoder options specifically for these applications to ease the certification burden on the OEM.

In the medical market, we are seeing an explosion of various medical devices and surgical robotics as well. Perhaps even more than in the industrial space, the safety levels and redundancy are paramount for these products as they can be involved in very sensitive and precise surgical and medical procedures. Advancing automation further in this industry allows for newer and less invasive surgical methods and access to high-end medical procedures in remote areas.

With the prospect of supply chain issues staying with us well into 2022, we’ve seen several motion control suppliers giving their customers a heads-up to plan for very long lead times (up to 6 to 12 months for some products!). How do you see customers — especially end users and integrators, who work on more of a project-by-project basis — dealing with the longer lead times and uncertainty in the supply chain?

Kevin Taylor, Encoder Products Company

Customers that are coping well are broadening their vendor portfolio, securing more inventory, and maintaining a strong internal work force. EPC’s motto is “Your Responsive Experts in Motion Control” and customer care is one of our key differentiators. Many customers are reaching out to us to help address gaps in their supply chains.

Jonathan Dougherty, HEIDENHAIN

Lead-time challenges have definitely been an obstacle for everyone during the recent year. Of course, proper planning and communication with your supply chain is the most important aspect of managing these increases. Having a supplier you can trust and have an open conversation about what to expect goes a long way in this regard.

Leave a Reply

You must be logged in to post a comment.