It’s hard to believe I’ve attended various iterations of MD&M West for more than two decades with just a few years missed. In fact, I was just reminiscing about the first-ever tradeshow of any type I attended in our industry — the 2002 National Manufacturing Week at Chicago’s McCormick Place. I was so young that I’d decided to fly to the city a day early to do some sightseeing. It was March 18, 2001 to be exact … one drizzly cold day after St. Patrick’s Day. The experience was indelible.

Anyway, this week finds me not in Chicago but in Anaheim, Calif., for the 2026 MD&M West show, including the rebranded Automation Technology Expo or ATX West pavilion … especially the Design & Manufacturing and Automation Sectors.

Here are just some of the motor and gearmotor-related technologies we saw and discussed at the show.

New automation technologies for medical and adjacent industries include motors, gearing solutions, vision systems, and feedback to support digital transformation (DX) initiatives from device makers, automation OEMs, and their suppliers.

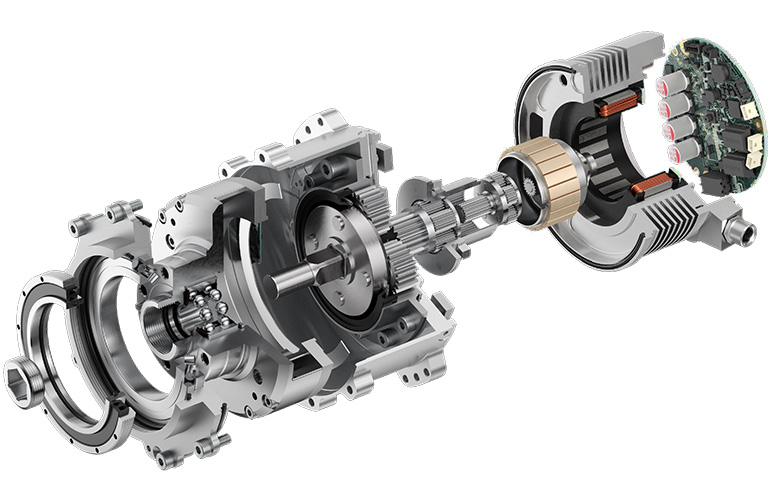

With Maxon USA, we chatted with Peter Van Beek about robotic joints for both mobile robots and stationary (or traversing facilities on seventh-axis systems) those industrial-grade articulated six-axis robotics. Van Beek detailed Maxon’s high efficiency joints integrating planetary gearboxes and frameless motors as well an encoder for commutation and an encoder for precise positioning. In fact, the assemblies deliver efficiencies exceeding 90% … a capability useful for battery‑powered platforms relying on high system efficiencies for longer runtimes.

On one final point, Van Beek was pretty clear — the same efficiencies aren’t available from joint variations with strain-wave gearing. But both joint families are modular, so integrators can specify gear ratios, brakes, torque sensors, and mechanical interfaces (as well as connectivity interfaces to some extent) interfaces for surgical robotics, laboratory automation, and other high‑end systems.

Another supplier with Swiss roots is also exhibiting at MD&M West this year — Boreasa. The company’s name derives from Boreas, the ancient Greek god of the north wind as its original focus was air-moving products such as miniature blowers as well as axial and centrifugal fans.

Now the supplier has expanded its offerings for miniature motion and automation applications with two-pole and four-pole high performance brushless dc motors engineered in Switzerland and then (for cost effectiveness) manufactured in ISO 9001–certified facilities in China. Other offerings include drivers and motors for various consumer, industrial, medical, and military applications.

“We offer the highest power density in the motor sizes we’re displaying here [at this show] with a patented core,” said Loic Lachenal of Boreasa in our conversation at his booth. High-grade magnets, high copper content, and advanced thermal dissipation and key, he added.

Lachenal also explained the ease of use of the D30/5/4QF-E2 four-quadrant digital controller and D30/5/4Q-M1 evaluation board on display.

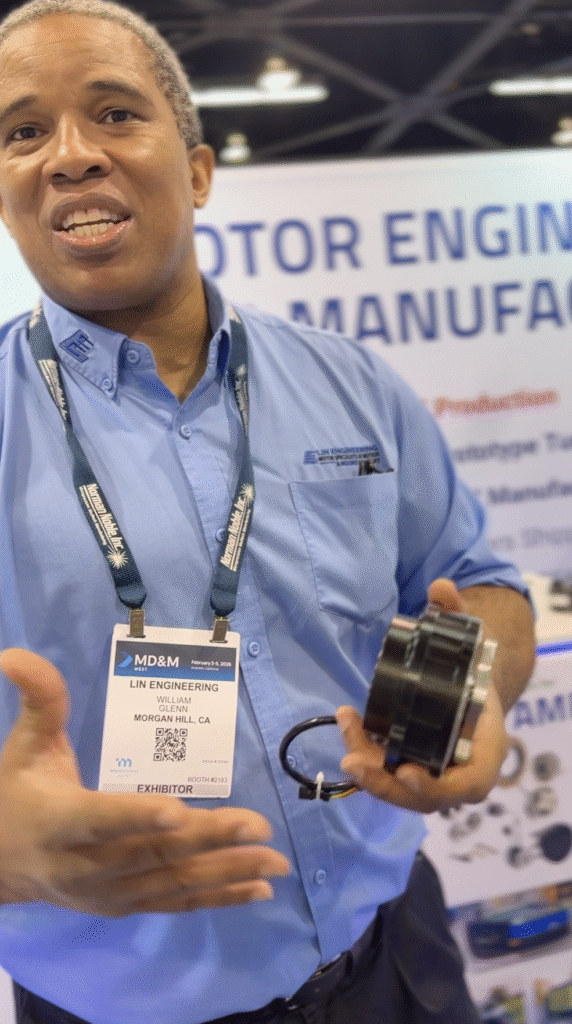

During another booth visit, William Glenn at Lin Engineering (who also knows all the best restaurants in Anaheim for carnivores) emphasized frameless motor technologies for robotics. “Old-school robotic arrangements cantilever a motor and gearbox off each joint. But now, it’s common to embed motor rotors and stators right inside the joints. Here, Lin Engineering can supply custom or stock frameless motors from standard sizes. We can also integrate frameless motor subcomponents into a frame with drive electronics on the back and a planetary or strain-wave gearbox in the middle.”

Other motor companies increasingly act as application‑engineering partners. In a discussion at Dings’ Motion USA, Peter Thornton described how motor projects Dings’ serves in medical, robotics, aerospace, and defense are often semi‑custom. So, application specialists often work backwards to get information about the environmental conditions, duty cycle, and regulatory needs to guide the design engineer toward the right combination of motor, gearing, and control.

At this show, there’s always also lots of emphasis on robotics and motion applications that overlap with medical designs. In fact, SDP/SI cites robotics and aerospace as their strongest growth markets currently. On display at the supplier’s booth — gear, belt drive, coupling, guide, and other mechanical components (especially in miniature variations) go into industrial automation equipment, mobile, surgical, and even humanoid robotics.

A longer conversation with Terry Auchstetter at Bodine Electric Co. (during which we luxuriated in chair technology at the booth) also reached beyond medical applications. In fact, our talk meandered all the way into cold‑storage and cryogenic‑adjacent applications (such as those for cannabis distillation) needing specialty subcomponents. We also chatted about motor-insulation grades, bearings, and specialized features for other extreme environments (such those that happen to present an explosion hazard). We also touched on the topic of self-locking gear types.

In fact, the latter is often misapplied, because no gearing is absolutely self-locking.

“Any locking function has to be from a stop, but some engineers confuse static self-locking with braking,” said Auchstetter. “So they think a self-locking gearbox will come to a quick stop and hold the payload when power is cut. Well, no — inertia will keep the axis turning; the gearing is only self-locking once it’s already at a dead stop.”

Expect more details in coming months on these topics as well as gearmotor uses in warehouse automation — including those for shipping-dock safety equipment, motorized vehicles, and robotics in digital commerce and fulfillment operations.

Key is that design engineers define system requirements with accuracy and that purchasing managers reconcile technical needs with budget constraints.

In another enlightening chat, Gene Matthews with Kollmorgen of Regal Rexnord shared his insights on aerospace applications — more specifically, designs for satellites, rovers, and other spacecraft needing frameless, embedded motors that can withstand the extreme environment of space. The company supplies motors that have flown on Mars missions and various orbital platforms, often in custom or semi‑custom variants tuned to each mission profile.

“Today, it’s no longer the old A&D market. Rather, work has really segregated into separate aero, space, and defense markets,” said Matthews. “It used to be that space was a really tiny market, so the opportunities were far and few between. Designs were one-off very expensive designs for NASA and those types of projects. Now, space companies have proliferated and they’re putting tons and tons of designs in space — and the industry is really booming.”

Some companies really specialize in designing for space applications, added Matthews … and what’s more, outer space is totally different than low-Earth orbit, as they’re very different environments. “For example, some are -200° C and others are 20° C. Some designs shield components from radiation and the highs and lows of the space thermals and others expose them to the environment.”

Expect more on this from Design World soon — and more on motion technologies in factory automation, where the challenge is not the vacuum of space but the inertia of decades‑old equipment. On this topic, Matthews described older U.S. operations as prime candidates for DX initiatives — including those still emphasizing high‑mix low‑volume end products (for their high profit margins) but especially those looking to output high‑volume end products.

Leave a Reply

You must be logged in to post a comment.