Engineers at Federal Industries Inc. in El Segundo, CA were tasked with developing a test protocol and supporting hardware for a complex planetary gear box that is at the heart of the centerline hose and drogue in-flight refueling (IFR) system for a new US Air Force tanker aircraft. As a subcontractor to Sargent Fletcher Inc., the primary contractor for the IFR system, Federal Industries had teamed with FO Engineering of Valencia, CA to design and build an actuation system that brings major improvements in safety, reliability and maintainability to the difficult and dangerous task of refueling aircraft in flight. The gear box is the key link between the radically improved variable displacement hydraulic actuation system and the hose reel that carries the in-flight refueling hardware.

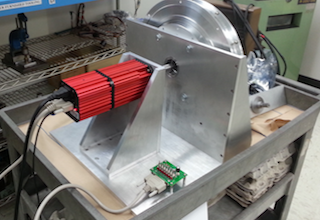

The gear design must have minimal hysteresis and backlash in order to accurately control drogue position while withstanding high forces from hose extension and retraction and high amplitude hose oscillations from multiple aircraft engagements with the drogue. Run-in and testing of the gear box after initial assembly requires a complex profile to properly seat and mesh the gears. After looking at various alternatives, project engineers decided the optimum solution for running this profile was the I2 Motor from Specialty Motors of Valencia, CA. The compact, integrated architecture of the I2 Motor simplified the task, reduced design time and cut development cost. The I2 Motor is an integrated servo system that incorporates a brushless DC motor, power supply, amplifier, programmable inputs and outputs and drives in one compact package, eliminating the need for separate components, connections or wires required to control or run the test. Integrating the test stand motion control system only required mounting the motor on the test stand and plugging it in.

The run-in and test program required 19 different commands with a unique speed, direction, acceleration, deceleration and run time for each. It was programmed in just a few minutes with a standard PC using the indexing feature of the I2 Wizard host software.

Once the set up was complete, the profile was downloaded to the motor controller, with the PC no longer required to run the test. The I2 Motor at the test stand is controlled with switches on an integration board, eliminating the need to take a computer into the shop environment.

The gear box directly controls extension, retraction and relative position of the IFR hose and drogue. The drive system has a number of advantages over current IFR control systems that rely on 40-year-old technology based on mechanical linkages and microswitches. Solid-state electronics replace older components and result in a system that is lighter, more reliable and easier to maintain.

But perhaps the biggest improvement with the new system is overall safety. Flying an aircraft to successfully engage the drogue trailing behind the tanker is a difficult maneuver that requires extremely precise control.

The IFR probe of the aircraft receiving fuel must hit the drogue with enough force to engage latches inside the “basket” that allow fuel to flow but not so hard that it causes slack in the hose. With the tanker and receiving aircraft flying at 180 to 320 knots (nautical miles per hour) closure speed with the drogue must be maintained within a 2 to 4 knot window. The margin for error is often less than 1%. If closure speed is too fast and the IFR probe hits the drogue too hard, it can set up an oscillating sine wave that causes the drogue to flail and may result in significant damage if it hits the refueling aircraft.

Specialty Motors, Inc.

Leave a Reply

You must be logged in to post a comment.