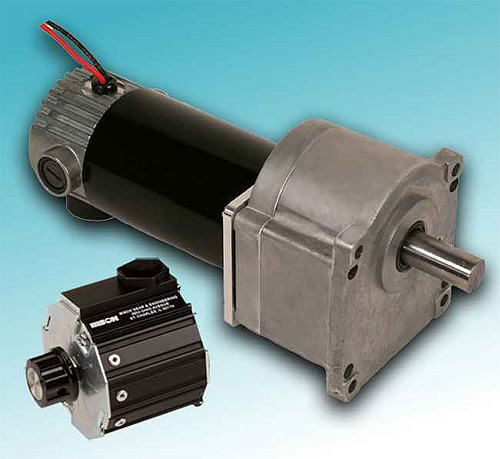

St. Charles, IL – Bison Gear & Engineering introduces six standard models of new parallel shaft permanent magnet DC gearmotors with continuous torque ratings from 30 to 500 in-lbs. (3.4 to 56.5 N-m). The new VWDIR134 DC gearmotors are available with 1/10 or 1/11 horsepower (74.6 or 67.8 watts) 90 volt brushed DC electric motors. The compact, integral gear reducers feature hardened steel helical and spur gearing for efficiency and durability, with ratios ranging from 10:1 to 266:1 and corresponding fixed output speeds from 152 to 6 RPM. The gearmotors feature built-in face mounting, compatible with Von Weise Genesis mounts, and offer overhung load (OHL) capability of 300 lbs. (136.4 kg.). For added versatility, these gearmotors also accept the new Bison TightDrive™ speed control.

Bison Gear’s TightDrive™ motor-mounted speed control can be easily user installed on the rear of the VWDIR134 gearmotors and offers up to a 20:1 speed range. The TightDrive™ is housed in a durable aluminum extrusion which offers NEMA 1 (IP 30) protection and superior heat dissipation. Speed is controlled with a combination on/off switch and speed potentiometer. In addition, three easily accessible adjustable potentiometers provide settings for minimum RPM, maximum RPM, and current limiting. The simple, yet innovative, SCR control architecture also provides much tighter speed regulation than alternative controls.

The TightDrive™ is designed for 115 volt 50/60 Hz operation and comes complete with three foot (0.9m) power cord and NEMA 5-15P plug. Users can mount the drive directly to the motor in 90° increments to optimize position of cord exit and motor leads.

The new VWDIR134 DC parallel shaft gearmotors are designed for high torque commercial, industrial and agricultural applications such as in foodservice, office and medical equipment as well as a wide variety of conveying equipment.

Bison Gear’s Innopreneurial™ application and design engineering capabilities to customize standard models to meet specific OEM needs are readily available. All of the VWDIR gearmotors are manufactured in Bison Gear’s suburban Chicago facility to Bison’s high quality standards in order to ensure a short supply chain and reliable, long-life operation. The VWDIR and TightDrive™ products are part of Bison’s new In-Stock, Instant-Ship (ISIS) program that offers same day order fulfillment on over 550 standard Bison products.

The VWDIR134 DC gearmotors are the thirteenth series to join Bison Gear’s comprehensive line of Von Weise Drop-In Replacement gearmotors. Bison’s VWDIR line now encompasses 90 standard models of right angle, parallel shaft, and offset parallel shaft designs utilizing AC, DC and universal electric motors from 1/30 to 1/2 horsepower (25 to 373 watts), with fixed output speeds from 1.5 to 181 RPM and continuous torque ratings up to 800 in-lbs (90.4 N-m). All of the VWDIR gearmotors are manufactured in Bison Gear’s suburban Chicago facility to Bison’s high quality standards in order to ensure a short supply chain and reliable, long-life operation.

Bison Gear & Engineering Corp.

www.BisonGear.com

Leave a Reply

You must be logged in to post a comment.