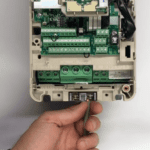

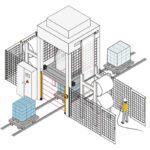

Mitsubishi Electric Automation, Inc. has released the newest addition to its lineup of variable frequency drives (VFD), the FR-E800 Series. The micro-drive features a built-in PLC, and will include safety functionality meeting IEC 61508 standards and support various networks, including Ethernet/IP, MODBUS/TCP, and the soon-to-be-released CC-Link IE TSN. The FR-E800 Series is designed for engineering, technology, and product managers in industries such as packaging, material handling, food and beverage, and water and pumping, as well as those who are adopting PM (permanent magnet) motors to improve their energy efficiency.

The FR-E800 is built upon Mitsubishi Electric’s proven variable speed control technology through years of reliable operation across various applications. It incorporates advanced capabilities in a compact footprint allowing for bookshelf style mounting. Additional features include extended programming functions, advanced fault detection features, and auto-tuning of PM motors for applications where energy efficiency is extremely important. The auto-tuning function includes configurable parameters to reach optimum performance, higher torque, faster acceleration, and lower noise level for quiet operation. This results in efficient control of motors and equipment to meet or exceed energy efficiency regulations.

For those OEMs that use induction motors in their equipment, the FR-E800 can control both induction and PM motors, helping to consolidate inventory and spare part management. The drive series is also dual-rated for light duty and normal duty, which may help achieve desired performance in smaller frame sizes.

“The FR-E800 introduces advanced features previously not available to micro-drives,” said Deana Fu, senior product manager at Mitsubishi Electric Automation. “From PM motor commutation and tuning to corrosion detection, and life time diagnostics of critical components, we feel that the FR-E800 will make a significant impact on manufacturing and HVAC.”

For more information, visit https://us.mitsubishielectric.com/fa/en/.

Leave a Reply

You must be logged in to post a comment.